According to an alert issued by Queensland's Mineral Mines and Quarries Inspectorate, workers were tasked with installing a belt on the conveyor.

They were using a loader and 14mm synthetic fibre rope to pull the old belt off the conveyor when a gravity take-up unit pulley jammed and the rope snapped, whiplashing into the unlucky man's face.

The eye was so damaged he later needed surgery to remove it.

No exclusion zone had been set up despite the dangers posed by cables, ropes and chains under tension.

The inspectorate said purpose-built equipment such as winches, winders or reelers were not used when replacing the conveyor belt and no-one working in the area was wearing appropriate personal protective equipment to protect them from flying materials or objects.

Winches allow for a more controlled belt pull on process and can be operated from a safe distance.

They can also be fitted with load cells so wire cable breaking strain is not exceeded.

Given natural fibre ropes were more prone to degradation when subjected to wet and muddy conditions over time and traditional synthetic fibre ropes such as nylon and polypropylene were prone to whiplash or failure, the inspectorate said newer high modulus polyethylene ropes should be used.

It said PPE should also be a must, with eye protection to always be worn.

Investigations into the incident are ongoing and further information may be published as it becomes available.

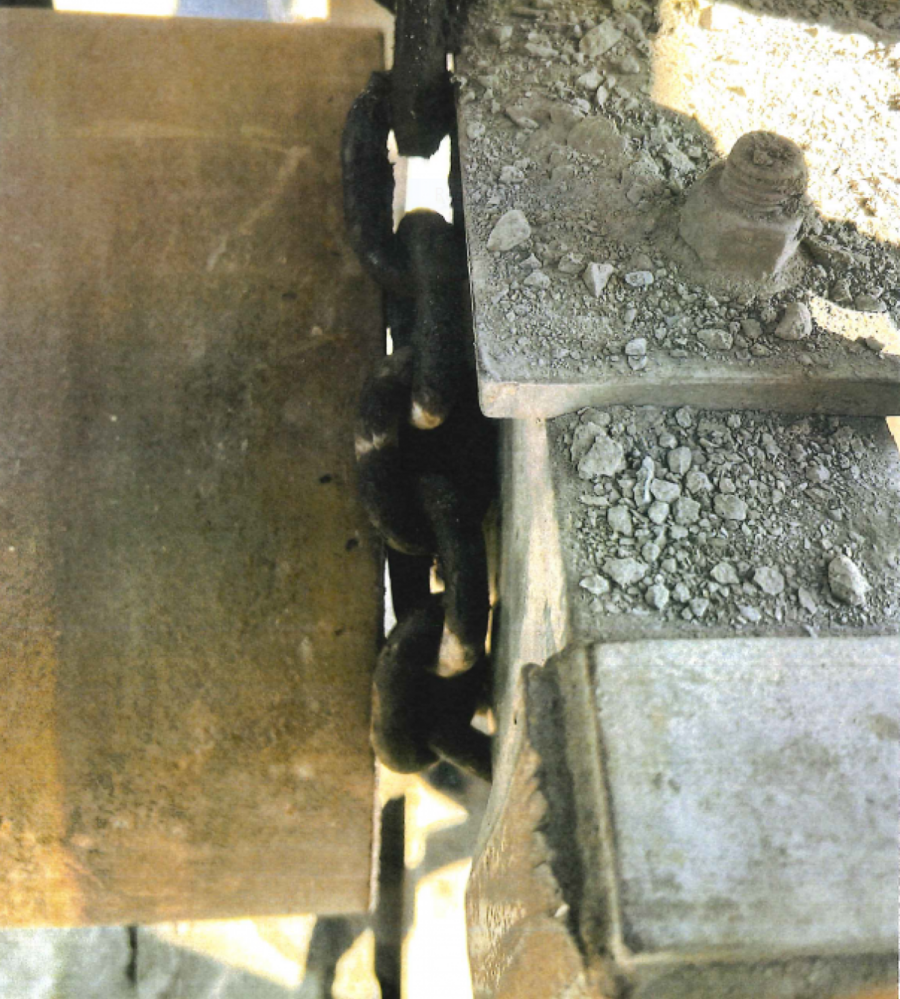

Jammed gravity take-up pulley.