Published in May 2006 American Longwall Magazine

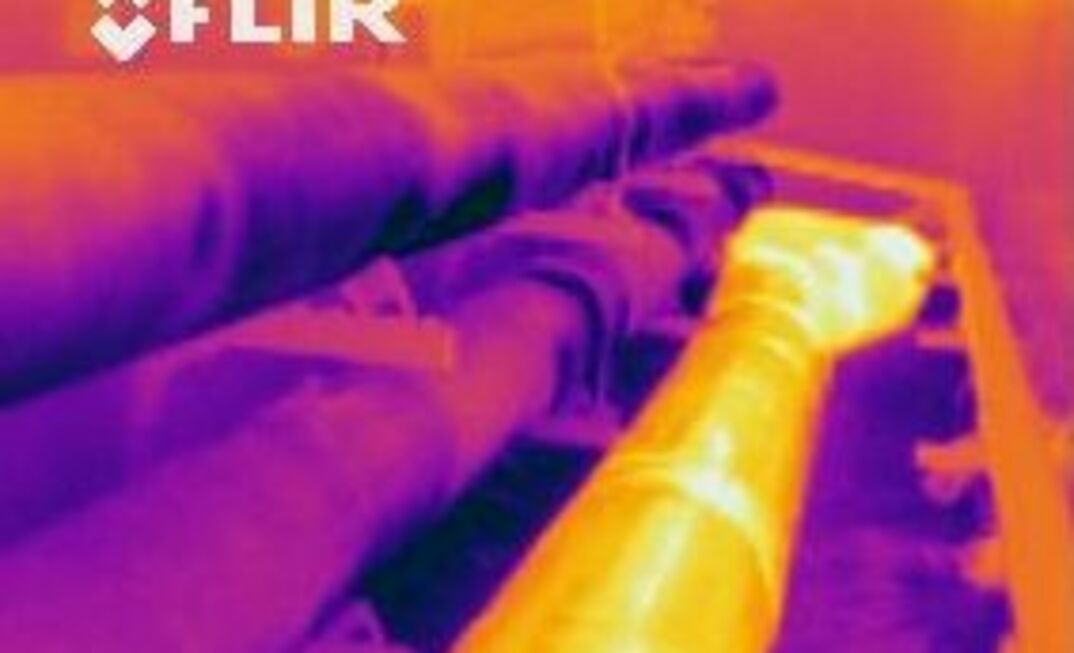

To prevent unpredicted downtime caused by the interruption of a power source or breakdown of a mechanical system, infra-red specialist FLIR Systems has introduced its ThermaCAM infra-red camera to the industry. The camera can be used to scan all electrical and mechanical systems to identify hot spots and intervene before failure.

“Nearly everything gets hotter before it fails, making IR cameras the perfect diagnostic tool to monitor equipment in many diverse applications, including the mining industry,” the company said.

Thermography is the use of infra-red cameras to not only “see” heat emissions but also measure the output, thus enabling the detection of equipment operating outside of normal temperature parameters – requiring maintenance, possible parts replacement and with the potential (and hazard) of imminent failure.

Infra-red cameras are widely used for electrical inspections of circuit breakers, transformers, fuses, disconnect switches and panels. As electrical connections become loose, corrosion becomes evident; if there is an increase in the resistance of current, connections can become hot.

Eventually if these bad connections fail, unplanned outages and potential injury can occur. In addition, prior to failure, the efficiency of the electrical grid becomes low because energy is spent generating heat, causing unnecessary losses, FLIR said.

Infra-red camera systems can detect temperature differences as small as 0.05C. Since a typical electrical failure occurs when there is a temperature rise of over 50C, thermal imagers can pinpoint these problems well in advance of a failure.

Mechanical systems such as bearings, motors, pumps, compressors and conveyor idlers can also be scanned for operation outside of temperature norms. For example, if there is improper lubrication or overloading of equipment, a mechanical system will increase in temperature, which can easily be detected with an infra-red camera.

Thermography can also complement other forms of predictive maintenance such as vibration analysis and ultrasound. For instance, when comparing banks of motors, thermographic inspection can instantly identify even minute changes in temperature readings on bearings and couplings and other internal workings (showing the existence of a problem), which may be further investigated, verified and located within the motor via other methods.

FLIR’s thermal imaging cameras come with software to make it easy to document findings and create maintenance reports.