Published in the August 2007 American Longwall Magazine

Initially introduced in 1985 to help miners evacuate in the event of fire or explosion, the CAB Lifeline is still produced as a rescue option to assist with both escape route direction and keeping groups together.

"Research [by industry agencies] has determined that the use of Lifeline can significantly improve the chances for a successful escape when a fire breaks out in an underground mine," CAB spokesperson Allen Smith told American Longwall Magazine.

"Its sturdy directional cones will help lead employees to the slope and shaft rather than getting lost or confused in an actual emergency."

CAB first joined forces with the National Mine Service Company and the Galatia mine, then owned by Kerr McGee, to develop a prototype following the 1984 Utah Wilberg explosion that took 27 miners' lives. Since that time, Smith said the group's research and development efforts on the lifeline and other products are a "constant process".

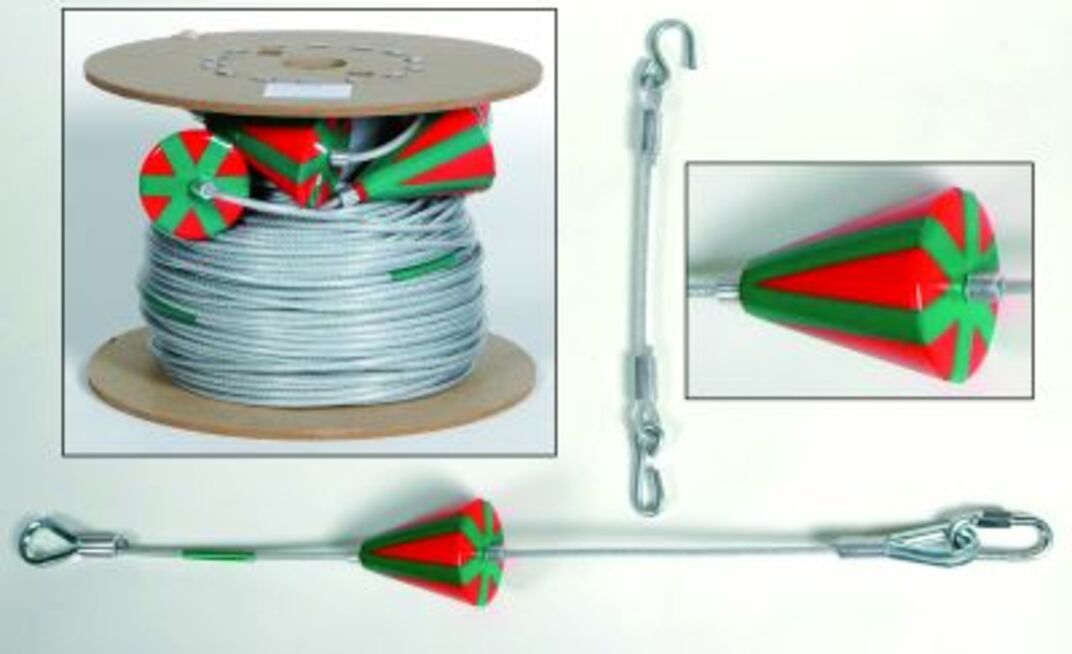

The product is available in two styles, rope and heavy-duty aircraft cable. The polypropylene rope style, made in 1/4-inch diameter and flame retardant, is sold in 300ft and 1000ft lengths, and the latter model is 3/16in plastic-jacketed galvanized aircraft cable and is available in a 300ft length.

Additionally, the Lifeline product is made in both a standard and extra high visibility design. The standard is outfitted with 2in reflective bands at 25ft intervals, while the latter style features high visibility reflective markers at the same 25ft interval, attached vertically, and at 2in by 4in in size.

The markers, Smith noted, can be seen regardless of the direction one is facing underground. "Because of their size and firm attachment to the Lifeline with aluminum stop sleeves, they will stay oriented to show the proper direction of escape - at all times."

While all orders are to distributors rather than directly to mines, most recipients of CAB Lifeline request several thousand feet at a time, he said. Once an order comes into CAB's offices in south-central Pennsylvania, turnaround to delivery is typically only one or two weeks.

No matter the type, the CAB Lifeline boasts several advantages compared to other similar products, perhaps most notably its handcrafted production rugged standards by individuals at CAB's facilities. Once it arrives at its mine destination, no assembly is required and it can be quickly installed by workers themselves onsite.

The cones, which when used correctly will lead workers from the mine by allowing their hands to slip over its exterior, are also one-piece construction and are already mounted on the line when purchased. Smith said CAB's strict quality control process ensures that the cones, made to stay secure and rugged in the harsh environment, and lifeline remain intact regardless of the level of wear and tear they take on.

CAB has made the cones easy to find in smoky and low-light conditions as well. Six reflective bands can be found on each one, and customers can choose between having the directional feature applied to the tapered and blunt portion of the cone, or the tapered section only.

With research and development remaining a vital part of CAB's mission into the 21st century, Smith said its product offerings grow and are improved upon every day. In fact, approval from the Mine Safety and Health Administration was just recently obtained for the rope lifeline, allowing its safe use at any mine nationwide.

Last year, the company developed a rescue tagline that allows up to 15 workers to stay tethered together when exiting a mine in an emergency situation. The tagline has 3ft tethers with 5ft spacing, which is far enough to provide room to move and even to crawl if the situation requires.

The company also produces hooks and hangers, cable rings and saddles and mine safety products to support electrical cables, pipe, tubing and various types of wiring both above and below ground.