Published in Australian Longwall Magazine

The Inspectorate’s Safety and Health division published a safety bulletin in October 2000 which indicated that in several instances the systematic application of cuttable bolts had failed to provide intended support to the rib.

The review found over-torquing was one of several factors causing cuttable rib support failure.

“Over-torquing of bolts during installation (was) causing the bolt to be weakened. In extreme cases the bolt has deteriorated to the point of immediate failure, which may not be detected by the operator. On later inspections the head of the bolt has been found to break off behind the plate. This result is influenced by high torque levels on machine mounted rib bolters. The sign of bolt weakening was masked by the plate,” the bulletin said.

At the time of the report’s release, New South Wales based Roadway Reinforcement Services had begun to develop the thrust system to overcome some of the problems associated with over-torquing.

Roadway Reinforcement Services’ Ghassan Skybey said the thrust doweling system overcame over-torquing by ensuring the dowel was properly installed.

The system was introduced in early 2001 at Oaky North Colliery and has since been adopted by a number of coal mines in NSW and Queensland.

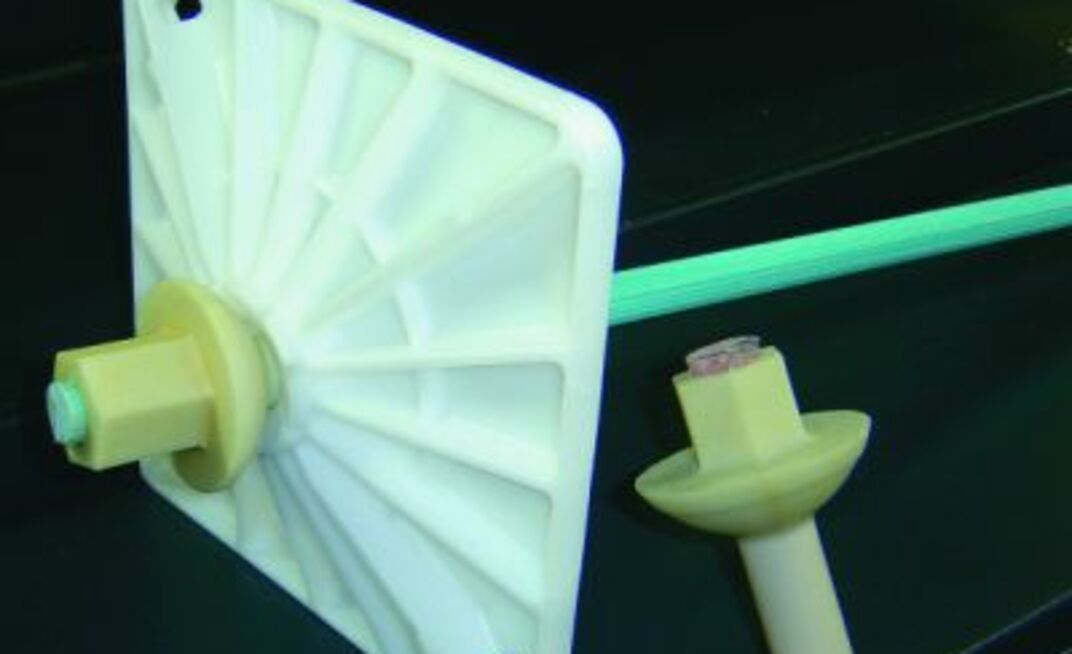

The thrust system consists of a hexagonal head moulded on to the end of a fibreglass dowel and concave-shaped plastic plate. When thrusted it acts as a spring, loading the dowel up to 20kN.

Skybey said the dowel installation was simple and based on a spin, thrust, hold method. This involved spinning through the resin until it was thoroughly mixed, thrusting the plate to load the dowel, then holding the dowel until the resin was set.