Published in the May 2006 American Longwall Magazine

Hydra Mining Tools International believes mines wanting to reduce costs and extend shearer drum life will in future be using wet radial cutting systems instead of more traditional point attack cutting systems.

According to Hydra, not only will the change maximizse haulage rates and production performance it will enable operators to remain in compliance with dust regulations and reduce the risk of frictional ignition.

The company bases its assumptions on extensive research into shearer drum performance at Australia’s top producing mine, Beltana, and at UK Coal mines.

As shearer drums get bigger and stronger to match the growing power and capability of shearers, drum manufacturers have tended to increase the size of the point attack bits and the blocks that hold them.

However, according to Hydra chief executive Gordon McShannon, this has created a dust maker, partly because the point attack tooling system is a bursting tool.

“It has compromised the design of certain shearer drums because the increased size of the point attack blocks limits the number of blocks you can fit in the vanes of the shearer drum. The drums then over-penetrate, creating more dust, and this leads to the mine having to slow down the shearer or, in extreme circumstances, stop the machine altogether until the dust levels reduce,” he said.

On some high production faces increases in the size of blocks turn them into lump breakers, degrading the coal and creating fines and higher dust levels.

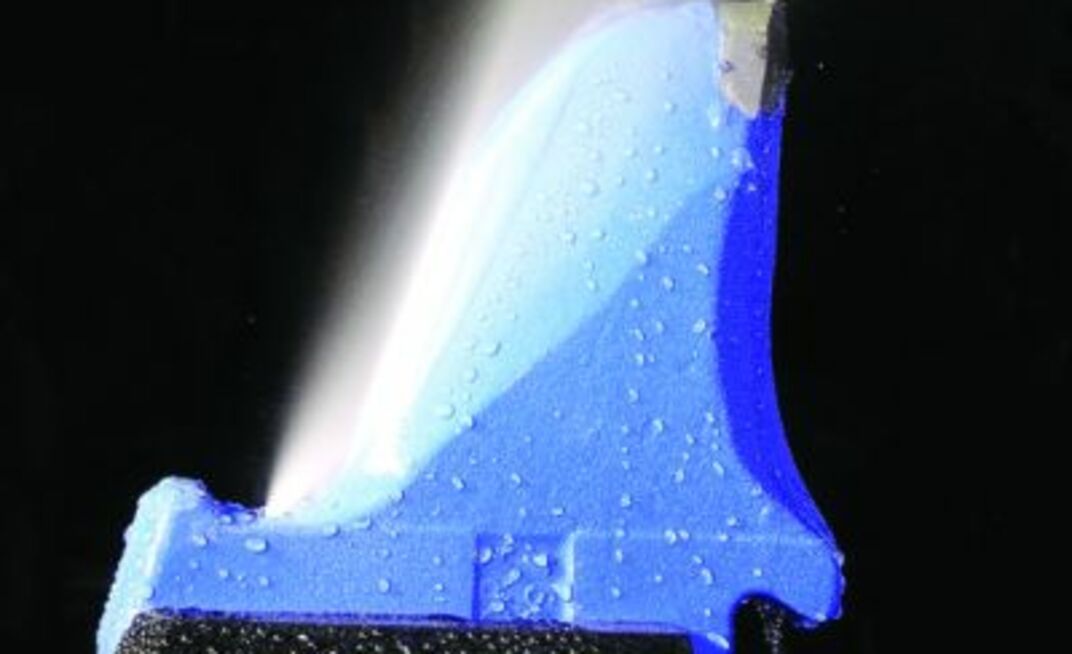

According to Hydra the answer lies in alternative cutting systems such as wet radial cutting systems, which can achieve adequate bit penetration at higher haulage rates without increasing dust levels or wearing blocks prematurely.

Because radial systems are a cutting tool – as opposed to a bursting tool – less dust is generated, along with a number of other advantages.

McShannon said wet radial cutting systems offered a number of benefits to longwall operators such as the ability to change bit reach depending on cutting conditions.

The traditional effective reach for bits on high production radial and point attack cutting systems has been 100mm but the new range of shearers with increased haulage speeds require longer reach bits to achieve the same effective reach as a radial tool.

It is not practically possible to increase the effective reach of the point attack bit much beyond 100mm because the shank and the block and sleeve would have to move in proportion.

The latest radial bits used at Beltana and UK Coal offer 130mm reach. Last November Beltana set new production records, producing 50,000 tons of coal in one day, 250,000 tons in one week and one million tons in a month.

“The introduction of this bit has allowed haulage rates to be increased, dust levels to be reduced and production records to be broken,” McShannon said.

If cutting conditions are difficult, operators can revert back to 100mm reach radial bits without making any alterations to the shearer drum.

This interchangeable bit system, from a standard 100mm to 130mm effective reach, increases bit penetration by some 30% allowing faster haulage rates. This feature cannot be replicated with any existing point attack cutting system, Hydra said.

Regarding dust suppression, water sprays directed at the cutting tip is the most effective way to suppress shearer-generated dust. The spray on the radial system is located in the block and is shrouded by the heel of the bit for protection but the spray on the point attack system is located outside the bit.

Hydra said experience has shown that the point attack spray housing is prone to washing or rapid wear when bit loss occurs. This leads to premature failure of the shearer drums due to loss of water pressure integrity.

Increasingly, Hydra’s new range of shearer drum designs allows mines to operate without cowls.

“I believe there are many mines that can benefit from moving to cowl-less shearer drums and achieve better cutting performances and quicker cycle times,” McShannon said.

Working without cowls allows an increase in shearer drum diameter, enabling the lead drum to cut more and the trailing drum to clean up better. Removing the cowl also enables the shearer drum to be closer to the conveyor to assist loading. Product size is greater and there is no build-up of localized gas pockets between the shearer drum and cowl.

A unique feature of the radial shearer drum is that it can be used interchangeably as either a coal laced drum or a rock laced drum without having to remove blocks.

“This is a unique feature of the radial shearer drum and is achievable because the blocks are located in the vanes and positioned flush with the top of the vanes,” McShannon said.

He does not believe the change to radial cutting technology will happen quickly, but added it would happen over time because there was a compelling argument to change.