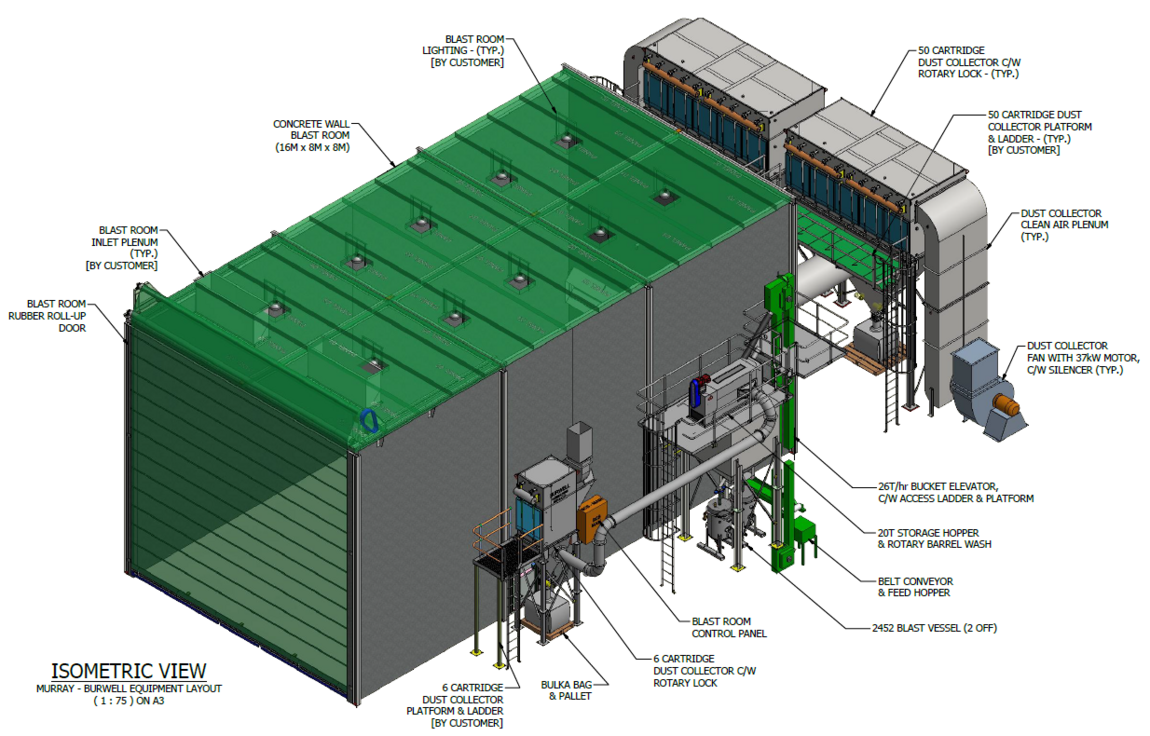

The new blastshed, featuring a state-of-the-art, Australian-made Burwell blasting system, brings all construction steelwork and equipment rebuild preparation activity in-house for the first time, enhancing quality and delivery control as demand for Murray's fabrication and machine rebuild services continues to grow.

Mechanical manager Shane Dunn says establishment of a complete one-stop-shop with the addition of the blastshed and eight new light fabrication bays will enable Murray to keep up with surging demand, which has doubled in the past two years. As well as the Burwell blasting unit, Murray is adding a pipe bender press and CNC band saw.

"The demand for blasting has gone up by 100% and our external suppliers have found it hard to keep up," he says.

"We blast a lot of our process steel for construction, and strip all the [rebuild] machines down to the chassis and do all the spray-paint preparation, including the blasting and crack testing, etc. The shot material is made from recycled steel, and is continually separated and reused after blasting, making the process efficient.

"Having a one-stop-shop gives us complete control over lead times and quality, and prioritisation of jobs."

Murray Engineering, which has more than 280 people working at the 55,000sq.m Pinjarra complex, currently has a double shift doing fabrication work, and about three months' work ahead of it.

Dunn says the expansion will increase capacity by about 30% and decrease lead time by 30%, while adding 12 new jobs.

New state-of-the-art Murray Engineering blastshed

Murray Engineering managing director Craig Lindsay-Rae says the company's recent SCA (Steelwork Compliance Australia) certification makes it one of only three companies in Western Australia with the accreditation.

"Following on from this, we are confident we can attain CC3 certification, which is a certification to conduct higher risk, more complex work."

Only nine companies Australia-wide have this certification.

"Bringing the blasting process back in-house will enable us to govern the preparation of painting surfaces with our ISO 9001 certification, and use our own trained team," Lindsay-Rae says.

"This eliminates any wait time between paint preparation and spray painting, streamlining the whole process and enables us to achieve a higher quality finish."

Construction work on the new blastshed underway

ABOUT THIS COMPANY

Murray Engineering

Contact:

Murray Engineering

54 Munday Avenue, Pinjarra

Western Australia 6208

Ph: +61 8 9550 5800

Email: info@murrayengineering.com.au

Web: www.murrayengineering.com.au

Murray Mining Services Mongolia LLC

Unit 303, City Center

Altangerel Street, 8th Khoroo

Sukhbaatar district

Ulaanbaatar-14200, Mongolia

Ph: +976-94059010/+976-99094814

Email: info@murrays.mn