Those who have taken the time to read this will probably have seen the awful video of the recent dam collapse at Vale's Brumadinho mine. I was pleased to hear the response from their CEO promising that Vale "will spare no effort" and "will take the necessary measures to solve the problem".

Are there wider community knowledge, understanding and expectations around tailings management? Rio Tinto recently published their survey of tailings dams in Australia. From this you could assume this leads them to review and manage these operations.

I'm suggesting that the most critical aspect of a new mining project is tailings management. Without a socially acceptable plan to responsibly deposit and rehabilitate these areas you have no project, and community expectations are increasing around dry tailings. Multiple technology options exist to produce and stack dry tailings. There are no technical limits to achieving this, only a cost implication.

Tailing Management is a large and complex business. Extensive studies on geochemistry are required to identify a suitable location; mining engineers and rock mechanic specialists are required to prepare the TSF; geotechnical consultants will define and plan the deposition of material and process engineers and equipment vendors design and provide the equipment appropriate to the deposition plan.

In our experience, the larger mining companies are in fact taking great steps toward alternative tailings handling initiatives. McLanahan was pleased to be offered an opportunity by Vale a number of years ago to participate in a project to assess the feasibility of initiating dry stack tailings for key sites.

This project involved working with site operations personnel and an Australian mining process consultancy, to undertake tailings slurry sampling in order to form a reasonable understanding of the sample range. Settling and filtration testing was conducted to a point where the client was sufficiently confident to invest in a pilot plant.

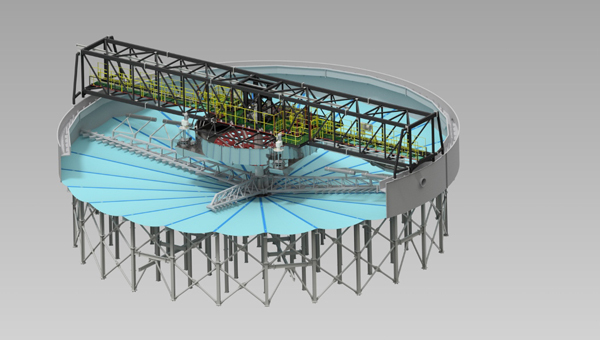

McLanahan Thickener design for pilot plant

Fast forward to the current time frame and McLanahan has been selected to manufacture the tailings thickener for this site. Our expert thickener team re-conducted onsite assessments to determine material variability and to review current tailings slurry output against the earlier baseline results. As expected, over a number of years the mining plan varies, depth of deposit changes and the mineral process is modified, giving rise to new optimisation initiatives in the pilot plant.

Example McLanahan Thickener

On a closing note, as society comes to accept the need to eliminate tailings dams and loss of life, all of the industry should be able to move in parallel to improve the safety and reliability in these areas.

Connect with Chris

https://www.linkedin.com/in/knowlescj/

References

https://www.youtube.com/watch?time_continue=1278&v=oTPMhaB9-kQ

www.riotinto.com/documents/RT_Tailings_and_storage_facilities.pdf

Images

https://www.amsj.com.au/vale-tailings-dam-collapses-leaving-nine-dead-and-200-missing/

McLanahan

ABOUT THIS COMPANY

McLanahan Corporation

Feeding, Crushing, Sampling, Dewatering and Scrubbing equipment.

HEAD OFFICE:

- 27 Kalinya Close, Cameron Park, NSW 2285, Australia

- Phone: +61 2 4924 8248

- Website: www.mclanahan.com.au

- Email: sales@mclanahan.com.au