LASE is one of the worldwide leading companies for laser-based sensor applications for the industry. We offer innovative and productive solutions by combining state-of-the-art laser technology and sophisticated software applications for several industry sectors.

Our product portfolio for the mining industry covers exact profile, volume and position measurement in bulk material handling operations for stockpiles, bunkers, conveyors, trucks and waggons. LASE is one of the worldwide leading companies for laser-based sensor applications for the industry. We offer innovative and productive solutions by combining state-of-the-art laser technology and sophisticated software applications for several industry sectors. Our proven turn-key solutions for the efficient bulk material handling are specially designed regarding industry needs and for extremely rough environments.

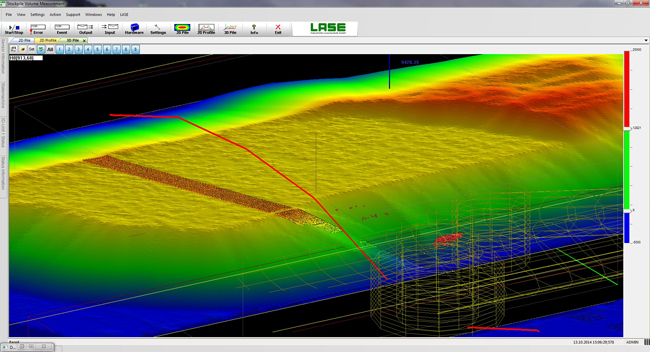

The LaseBVH (Bulk Volume Heap) measurement system is a laser based measurement system to measure volumes and profiles of stockpiles in open cast mining sites. It is used on stacker and reclaimer mining machines to retrieve data and further beneficial process information of heaps and stock yards during the daily bulk material handling operations. A retrofit to existing machines and the integration into existing storage or stockpile management systems can be done with manageable effort.

By using the LaseBVH system the end-user is able to continuously measure the exact volume and profile of the bulk material and use the data for continuous and reliable inventory management. Another mayor benefit for the end-user is to get data for a complete bulk material monitoring and management by an enhanced productivity through efficient scan runs of the used laser measurement technology.

In general it also can be specified that the LaseBVH system not only facilitates and optimised material management but also helps to increase safe operations by an optional collision prevention functionality to prevent collisions between the machine and objects, another operating machines or the machine with the materials. Concerning the last named functionality the current depth of the bucket wheel while excavating the material can be measured due to the installation of a further laser scanner device. Thus the optimal material quantity is transported over the conveyor and ensures reliable results for mass flow calculation.

For further information about our company, applications and products just visit our website https://www.lase.de/en or follow us on LinkedIn, Twitter and YouTube.

Contact:

LASE Industrielle Lasertechnik GmbH

Rudolf-Diesel-Str. 111, 46485 Wesel (Germany)

Tel.: +49 281 95990-0

Fax: +49 281 95990-111

Email: sales@lase.de

Web: www.lase-solutions.com

ABOUT THIS COMPANY

LASE

LASE is one of the worldwide leading companies for laser-based sensor applications for the industry.

HEAD OFFICE:

- Rudolf-Diesel-Str. 111, 46485 Wesel, Germany

- Phone: +49 281 95990-0

- Fax: +49 281 95990-111

- Web: www.lase.de/en

- Email: info@lase.de