Slurry pumps are only as good as their seals. As every industry operator knows all too well, the replacement and maintenance of packing and mechanical seals often represents extended asset downtime and the related loss of revenue during lengthy upkeep procedures.

Enter Chesterton, fluid sealing and equipment protection specialists, with an innovative remedy to this historical problem - the game-changing SpiralTracTM. Designed to work with both packing and mechanical seals, the unique design of this environmental controller is simple to install and greatly enhances sealing reliability that can be utilised within all rotating equipment.

So let's delve a little deeper into why this is such an advantageous addition to the slurry industry.

The Challenge

Ensuring patent seals within operational assets is crucial to a company's bottom line. However, in an industry where the integrity of seals or their packaging can be measured in weeks or, in harsh conditions, as little as days, the challenge of ensuring optimal production is further compounded by having to deal with multiple suppliers to meet their needs.

No matter what type of seal is in use, it's generally recommended to replace mechanical packing or service mechanical seals. However, in reality, this can be a time consuming and difficult task. This often leads to less than ideal practices, such as leaving lantern rings in place while repacking the rings above.

Add in the at times difficulties of installing mechanical seals and determining the best solution for the particular rotating machinery in use, and it's easy to see why various short-cuts often become the norm to keep downtime to a minimum and production at a maximum.

The Solution

The way forward was to draw up mechanical seal and mechanical packing standardisation guidelines for the slurry industry. This was done through a program of expertise and the ability to effectively produce not only the mechanical seals and packaging, but an effective solution that extended the life of both and had a positive impact on the many environmental aspects related to slurry.

The real lightbulb moment came with the creation of the industry-changing SpiralTracTM environmental controllers. This simple, yet highly-effective addition enhances sealing reliability thanks to removing solids and improving the cooling of the stuffing box. In turn this extends both seals and packing reliability and also reduces the cost of flushing in abrasive applications.

Of course, despite its complex role, it was imperative that the addition of SpiralTracTM with packing and mechanical seals was easy to install. The end result was a range of environmental controllers to be used with either mechanical seals or packing, and that offer the following:

- Installation requires no modifications to the pump or seal cavity

- Available in split versions

- Split design installs easily in the seal cavity

- Greatly reduces the flush

- Can be easily installed between the seal and seal cavity

- Multiple configuration options

- Enables venting of air from the chamber

With a variety of designs and that can be used with all slurry rotating applications, advantages over and beyond that of the purchase price soon become apparent. These include:

- Longevity of seals, packaging and shaft sleeves

- Less downtime

- Less maintenance costs

- Conservation of water

- Power saving

- Simple repairs

- Increased reliability

- Strong resistance to chemical aggression and abrasion

Chesterton's far-reaching expertise that spans the globe yet provides a truly local service has been crucial in the provision of such a ground-breaking solution. Technological advances and industry-specific knowledge have been tantamount in the production of a variety of slurry focussed mechanical seals and mechanical packing. By creating a range of leading seal solutions that offer simplified installation, improved reliability and extended performance, customers can easily target their bespoke application needs.

Seals and solutions on offer include:

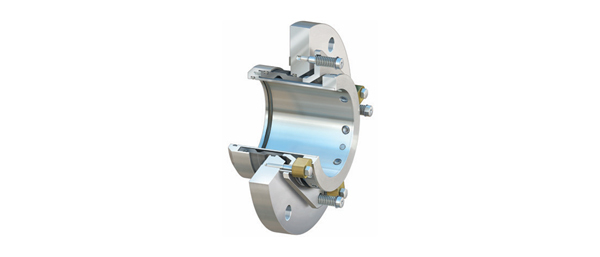

- 170 and 170L Slurry Cartridge seals

- 442TM Split Mechanical Seals

- 2180 Axius Modular Dual Cartridge Seals

- 2211 and 2212 Dualpac Slurry packing

- A variety of SpiralTracTM installations to support both packing and mechanical seals

- Flow Guardian Seal Support System

2211 and 2212 Dualpac Slurry packing

Slurry seal

With application parameters that support extremes of temperature and pressures, as well as a variety of capacities and in varied conditions, the use of SpiralTracTM is proving hugely beneficial to organisations that've taken advantage of this innovative opportunity.

Discovery How Chesterton's Slurry Kit Can Benefit Your Operation

Virtually all slurry transport applications can benefit from the use of SpiralTracTM with their seals and packing. Chesterton's experienced advisors will be delighted to discuss your particular situation and advise how your operation can benefit from what is truly a slurry revolution.

ABOUT THIS COMPANY

Chesterton

Stress, high impact, slurries, dust and dirt, corrosion, and lack of water can all have an enormous impact on mining equipment reliability and uptime. For decades, Chesterton specialists have helped mining operations around the globe meet these challenges with expertise and advanced solutions in sealing, lubrication, and protective coatings.

Chesterton Customseal is a joint venture between A.W. Chesterton Company and Customseal Australia. Chesterton Customseal provides our clients with innovative solutions in high-performance seals, combining the strong capabilities of two brands in one product.

CHESTERTON ASIA PACIFIC:

All Chesterton Products Distributors Channel

Chesterton Website - chesterton.com

CHESTERTON CUSTOMSEAL:

Chesterton Customseal’s industry-proven sealing solutions deliver the highest value by extending the hours of your operation between maintenance intervals of your equipment and increasing overall asset life. We provide sealing solutions as well as replacement kits for refurbished equipment.

Chesterton Customseal website - chestertoncustomseal.com.au

Chesterton Customseal address: 95 Excellence Drive, Wangara WA 6065

Contact us