It's the little things in life that count, and in the world of mining they don't come much smaller that the seals that drive the efficiency of rotating, stationary, and fluid power equipment platforms.

When it comes to reliability, much effort is directed to the larger components so vital for processing ability. However, a failure to pay the same devotion to the quality of the sealing solutions within these assets can lead to a variety of unfavourable outcomes, including:

- Reduced lifespan of components

- Lowered productivity

- Increased maintenance costs

- Unnecessary repairs

- Catastrophic failure incidents

When considering the ultimate in hydraulic seals for example, it's necessary to focus on the four following attributes:

- The seal material: Overwhelmingly, the most important improvement that can increase reliability is to upgrade the material that the seals are made from. A high-performing polymer ensures the ultimate suitability to the fluids within a system, the environment, the equipment itself and the operating conditions.

- The seal profile: This must be designed for the specific application, be able to effectively withstand high stresses and of the correct size to fit the equipment.

- The bearing components: The ability to handle incredibly potent radial forces is key for seal protection. Bearings should also keep contaminants out and prevent any metal-on-metal contact within cylinders.

- Configuration of the seal system: Customised, application-specific solutions designed by engineers is the crucial difference that ensures the highest level of performance.

Together, these key components of hydraulic sealing are what makes a very real difference in asset longevity, output, lowered maintenance costs and reduced downtime.

When determining the right seal solution, it's vital to ensure that all four of these factors have been adequately addressed. Only by selecting those that've been wholly designed in such a manner will the outcome be improved, thanks to reliability combined with maximum mining and ore processing performance.

The following lines in sealing solutions combine all of these attributes and are giving companies the crucial edge over their competitors.

Hydraulic and Pneumatic Sealing Solutions

Cutting edge polymer technology has been tested and embraced by those who demand the highest level in sealing applications. Such solutions extend the longevity of hydraulic seals, meaning machinery can work for longer before needing maintenance. Unique seal geometries are applied to both custom and turnkey cylinder repair kits, so improving productivity and consistency.

Visit chestertoncustomseal.com.au to discover more (Chesterton Customseal is a joint venture between A.W. Chesterton Company and Customseal Australia and produce high-performance elastomeric polymer seals designed for use in a wide range of hydraulic, pneumatic and rotary equipment).

Product: Mobile Mining Kit

Mechanical Seals: Pumps, mixers, agitators, and rotating equipment

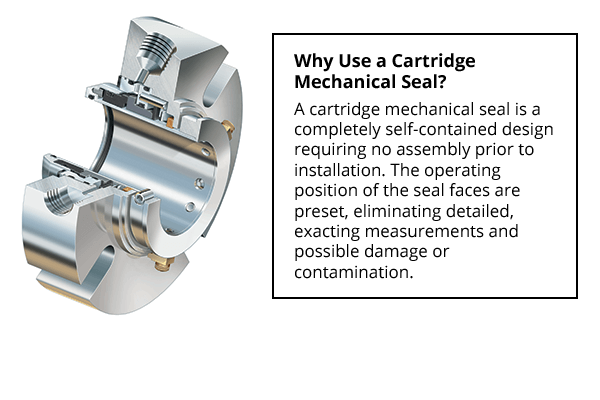

Utilising the four crucial components mentioned above, the highest grade of a variety of seals can be determined to achieve the most cost-effective and long-term solutions. These include:

- Cartridge seals

- Split seals

- Gas seals

- Dual seals

- Mixer seals

- A variety of sealing support solutions

Lubrication/MRO Specialities

Getting the crucial aspect of lubrication correct has a hugely beneficial impact on performance and production. Taking advantage of technologically advanced industrial lubricants, automatic lubricant dispensers, cleaners and greasers is the key component to ensure seal longevity.

Product: Chesterton 615 HTG: High-Temperature Greases

Protective Solutions for Metal Equipment

Ore processing applications have to perform under demanding conditions. Withstanding abrasion and corrosion at all levels is essential, and there are a variety of ceramic-reinforced ARC efficiency and protective coatings that can be applied to achieve this.

Product: ARC BX5 (MX5)

Packing and Gaskets for valves, pumps and flanges

Leakage has historically been a challenge, and it's vital to consider the most advanced packing and gasketing products and applications to combat this.

Product: Chesterton DualPac® 2212

Chesterton are World-Leaders in the Provision of the Ultimate Sealing Solutions

Today's highly-competitive industry demands the most innovative of sealing solutions. From new to renovated equipment, savvy site management and proprietors trust Chesterton's range to keep their assets running effectively and efficiently. Utilising the carefully designed combination of seals and related consumables, including mobile mining kits specifically designed for refurbished equipment, allows operations to meet the critical demands to remain competitive.

Discover the world of Chesterton seal solutions at www.chestertonrotating.chesterton.com and find out how taking intimate care of your assets smallest components can lead to considerably larger returns…

For our Polymer Seals solution visit https://www.chestertoncustomseal.com.au/who-we-serve/mining/

Download our mining catalogue following the link

ABOUT THIS COMPANY

Chesterton

Stress, high impact, slurries, dust and dirt, corrosion, and lack of water can all have an enormous impact on mining equipment reliability and uptime. For decades, Chesterton specialists have helped mining operations around the globe meet these challenges with expertise and advanced solutions in sealing, lubrication, and protective coatings.

Chesterton Customseal is a joint venture between A.W. Chesterton Company and Customseal Australia. Chesterton Customseal provides our clients with innovative solutions in high-performance seals, combining the strong capabilities of two brands in one product.

CHESTERTON ASIA PACIFIC:

All Chesterton Products Distributors Channel

Chesterton Website - chesterton.com

CHESTERTON CUSTOMSEAL:

Chesterton Customseal’s industry-proven sealing solutions deliver the highest value by extending the hours of your operation between maintenance intervals of your equipment and increasing overall asset life. We provide sealing solutions as well as replacement kits for refurbished equipment.

Chesterton Customseal website - chestertoncustomseal.com.au

Chesterton Customseal address: 95 Excellence Drive, Wangara WA 6065

Contact us