During March this year, most of the world was quickly engulfed by the COVID-19 virus. China by comparison, was moving past the virus and turning their attention toward its latest tailings dam incident. According to a Reuters report, China's north eastern province of Heilongjiang experienced a tailings dam leak at a molybdenum mine that threatened to contaminate the local water supply. Closer to home, mine tailings and the way we manage tailings storage is also coming back into focus.

Alternative energy increases tailings volume

All the new minerals required to meet the needs of electric vehicles, battery storage, PV solar and other alternative energy sources rely on processing, refining and concentrating these source minerals; this means more water and more storage for mine tailings. Lithium is already proving to be another super resource for Australia and there is strong support for not just mining but also refining and processing it on Australian soil. In 2019, a large lithium tailings storage facility in the form of sealed cells were proposed to deal with tailings from the Albermale lithium hydroxide plant in Kemerton WA. The interesting aspect of this arrangement was the outsourcing of tailings storage and management to a third-party contractor.

Is outsourcing of tailings beneficial?

According to a report from ABC news the facility was reviewed and certified by the EPA. Cleanaway, the liquid waste operator, intended to transport and operate the site which was already accepting tailings from a local titanium processing facility. Outsourcing tailings storage could have benefits for both miners and the community. Onsite tailings storage is problematic for miners, with relatively high infrastructure and ongoing costs along with the shear amount of space required. The offset for remediation has an impact on the economics and the mere presence of tailings dams can influence community sentiment and social licence.

Offsite storage and management potentially reduces costs by ensuring the material is delivered to a fit for purpose site, operated by organisations with the expertise to efficiently deal with this type of waste. This also frees up valuable land that can be optimised for continued or expanded operation.

Social licence to operate is one of the largest factors for mining to be acceptable by the broader community. Decreased footprint and reduced movements are initiatives aimed at regaining land and preventing further degradation.

Enduring Value™ Framework

Outsourced tailings management also has the potential to align with the principles of the Enduring Value™ developed by the Minerals Council of Australia. The purpose of the framework is to highlight the commitment by the mining sector to be safe, profitable, and environmentally and socially responsible. It acts as a benchmark for community expectations and outlines long-term benefits for society through effectively managing our natural resources. Relevant principles include Principle Six: Seek continual improvement of our environmental performance, which requires the safe storage and disposal of residual wastes and process residues. While Principle Eight: Facilitate and encourage responsible product design, use, re-use, recycling and disposal of our products, encourages innovative methods and technologies for resource recovery and re-use.

Standardising Tailings Preparation

In order to transport and treat tailings for outsourced offsite storage, miners would be encouraged by treatment specialists to reduce volume and prepare the tailings material. This would enable the tailings to be transported, stored and processed in a way that meets acceptable standards. In doing so it would also help to optimise the process to reduce the amount of water transported and improve processing times. In this case, up stream dewatering, clarifying and thickening becomes mandatory to prepare the tailings for transport rather than by-passing this stage and pumping direct to a tailings dam. Theoretically, tailings with higher solids content could deliver lower transport costs and higher liquid return to the site.

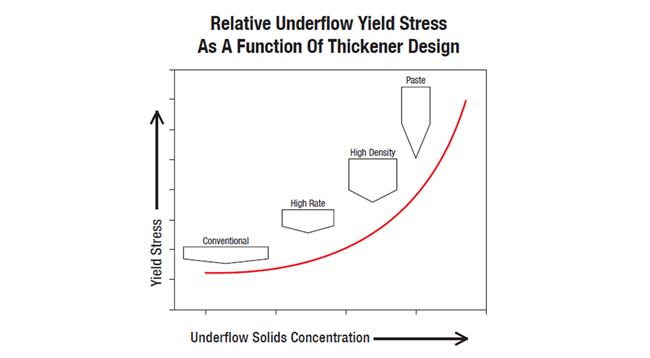

Thickeners are a low energy option that are ideally suited to effectively dewater tailings. They are broadly classed into three groups; high rate, high density and paste. Selection often depends on the underflow and its required purpose. If the material needs to be pumped a reasonable distance by a centrifugal pump, then a high rate Thickener is the obvious choice. For an application that requires maximum liquid recovery, with the highest possible solids content and a non-segregating thick deposit, then a paste thickener is more acceptable. The easiest way to view these options is to consider it on a Yield Stress Curve. Simplistically the yield stress provides a measure of how thick a material is or its resistance to flow. For slurries of the same particle size distribution the yield stress is proportional to the solids content. A high rate thickener will typically have a yield stress of 10-30 Pa and the material's consistency will resemble tomato sauce. A high density thickener's yield stress of 30-100 Pa resembles treacle, while a paste thickener's yield stress of 200-250 Pa is much more like toothpaste.

Thickener designers are often faced with a variety of competing influences because there is not necessarily a specification for the output. Consequently, the technology provided is a compromise based around the influences of cost, space, time and the final use of the underflow. Outsourced tailings storage and management may be a game changer where the liquid waste companies and the thickener designer are able to work together to set a suitable benchmark for the tailings as a ‘product,' with the possible side effect of getting better recoveries for miners and processors.

Connect with Chris

https://www.linkedin.com/in/knowlescj/

Images

The Greenbushes Lithium Mine. Australian Broadcasting Corporation (2019, August 28). Lithium's the next big thing, but proposed tailings facility at Dardanup tip faces backlash from framing town. Click here

McLanhan Corporation

References

Australian Broadcasting Corporation (2019, August 28). Lithium's the next big thing, but proposed tailings facility at Dardanup tip faces backlash from framing town. Click here

Cleanaway (2020). Banksia landfill in Dardanup, Bunbury, Western Australia. Dardanup Landfill. Click here

Minerals Council of Australia (2015). Enduring Value: The Australian Minerals Industry Framework for Sustainable Development. Click here

ABOUT THIS COMPANY

McLanahan Corporation

Feeding, Crushing, Sampling, Dewatering and Scrubbing equipment.

HEAD OFFICE:

- 27 Kalinya Close, Cameron Park, NSW 2285, Australia

- Phone: +61 2 4924 8248

- Website: www.mclanahan.com.au

- Email: sales@mclanahan.com.au