Leading graphene supplier First Graphene has grown from a two-man exploration outfit to a world-leader in the manufacture of graphene - the thinnest material ever isolated and a natural enabler that makes products better. Small additions of their PureGRAPH® added to existing products provide numerous advantages from increased mechanical strength, tear resistance, reduced wear rates, improved thermal stability, UV resistance, reduced hydrolysis attack and improved fire retardancy benefits.

Graphene was initially isolated as a single sheet of carbon atoms arranged in a hexagonal network which give rise to its unique structure and outstanding properties - a discovery that led to a Nobel prize for the two researchers responsible.

Industrial graphene products are powders which consist of 2-dimensional graphene platelets being just a few atoms thick. These powders are high performing additives that enhance the performance of industrial materials and components.

While manufacturers in the past have struggled to supply products of a consistent and verifiable quality at scale, in repeated production runs, First Graphene has pioneered the production of high-quality and high-performing graphene nanoplatelets in commercially available quantities, at an acceptable price to industry.

Through collaborative agreements with universities and other partners, First Graphene has accelerated the development, application, and commercialisation of graphene to consolidate its graphene technological leadership and reputation for innovation, quality and reliability.

The Australian-listed company has a robust manufacturing and supply platform based on a secure supply of high-purity graphite ore and an established 100 tonne per year graphene production capability.

First Graphene has arguably the largest graphene facility in the world; a 960sq.m custom-built production plant just south of Perth in Henderson, WA that is operated by a workforce of 12.

The automated plant processes 99% graphite ore straight from the ground and turns it into graphene using the company's proprietary single-step, highyield electrochemical exfoliation process to achieve the world's highest ore-tographene conversion rate.

The robust supply capabilities and five to six years' worth of raw materials stockpiled in WA offers Australian miners supply chain security, with all raw material and manufacturing based locally in Australia.

First Graphene Managing Director Craig McGuckin said graphene production has in the past been held back because companies struggled to make it at scale.

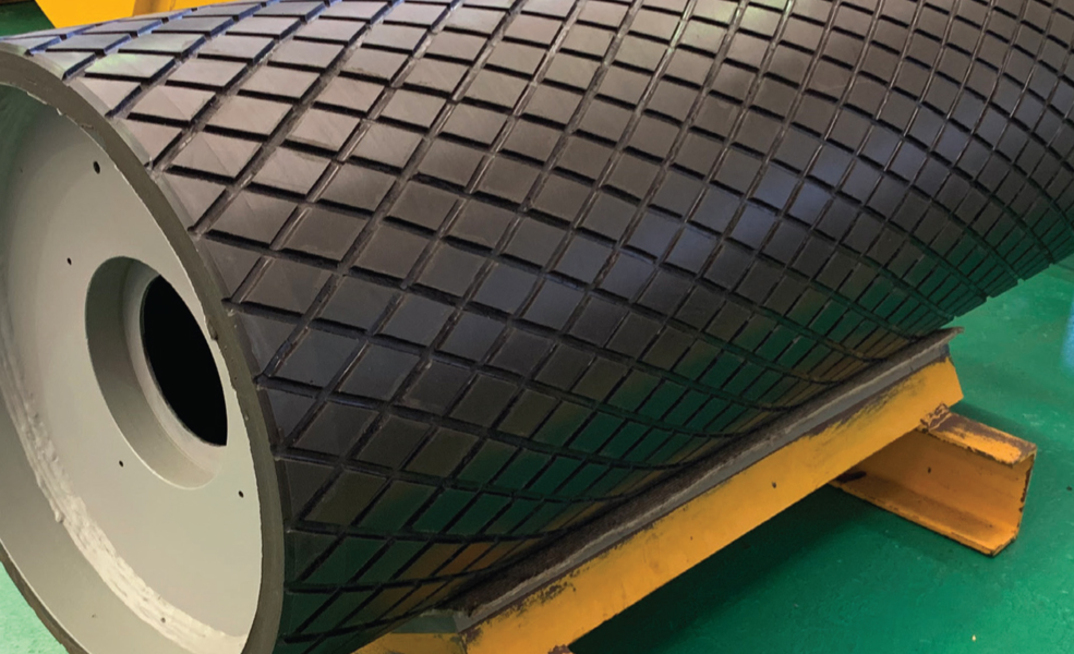

Photo courtesy of newGen Group

He said rather than focusing on the sexy stuff like high tech aviation or automotive industries, which takes 10-15 years of development and regulatory approval processes, First Graphene uses its graphene to make high-performing PureGRAPH® graphene powders to significantly enhance the performance of sacrificial wear liners, screen media, conveyor components and glass composites in the mining and mining related industries.

These advanced graphene nanoplatelet products are high-purity with very low metal and silica contaminant levels and are strictly quality-controlled for consistency.

McGuckin said the company is the only entity in the country with approval from the National Industrial Chemicals Notification and Assessment Scheme (NICNAS) to manufacture and sell graphene powders.

He said First Graphene also has Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) approval for the EU and UK regions, and they are a Tier 1 partner at the Graphene Engineering and Innovation Centre (GEIC) in Manchester, UK.

The quality analysis procedures for the bulk analysis of the material are extensive and the company can provide Certificate of Analysis and Material Data Records for each batch provided.

Commercial applications are now being developed in industrial composites, fire retardancy, construction and energy storage. PureGRAPH® graphene powders are low defect, high aspect ratio graphene platelets available in three product sizes.

PureGRAPH® 20 - particle size 20µm. This product is ideal where fire retardancy barrier, thermal conductivity and reinforcing properties are needed. Applications include protective coatings, concretes, and geotextiles.

PureGRAPH® 10 - particle size 10µm. This product is readily dispersed into polymer resins,rubbers and thermoplastics for excellent reinforcing properties. Applications include reinforcing of rubbers and carbon fibre and glass fibre filled composites.

PureGRAPH® 5 - particle size 5µm. This product is useful for formulations in low viscosity systems such as inks where solution stability and final film appearance is important. Applications include electrically conductive inks and coatings.

The product range has been developed to address specific market requirements, with further size options available upon request.

Due to its unique process First Graphene can produce graphene with larger lateral sheet sizes for particular applications.

PureGRAPH® products significantly improve the performance of wear components including bucket liners, piping spools and screen products.

PureGRAPH® products are easy to use with batch to batch consistency guaranteed through leading edge quality control testing.

Field trials have been held in the Pilbara with newGen Group and some major iron ore miners on PureGRAPH® enhanced bucket liners, with the product well and truly proving its mettle after 36 weeks in hot, dry and dusty conditions.

First Graphene has been working with newGen since June 2018 to develop graphene-enhanced polyurethane liners for use in mining equipment for leading iron ore producers, including BHP, Rio Tinto and Fortescue.

Adding graphene to the liners significantly reduces the wear factor and extends the life, which in turn enables companies to save on materials and labour costs.

First Graphene is also working on a research program with an established Malaysian rubber processor to test and demonstrate how PureGRAPH® can improve the performance of natural rubber products in the mining industry.

This has potential to bring generational change to the manufacturing of natural rubber products, with expected improvements in mechanical properties of strength, tear, and abrasion resistance.

McGuckin said miners need to ask themselves if they are really getting the best out of their equipment.

"Only First Graphene has the capacity to deliver high volumes of high-quality graphene to users when they adopt graphene into their products," he said.

ABOUT THIS COMPANY

First Graphene Ltd.

First Graphene Ltd. is the leading supplier of high-performing graphene products with a robust manufacturing platform and an established 100 tonne/year graphene production capacity.

HEAD OFFICE:

- 1 Sepia Close, Henderson, WA, 6166, Australia

- Telephone: +61 1300 600 448

- Web: firstgraphene.net

- Email: info@firstgraphene.net