WAM combines welding science, metallurgy, CAD software design and robotics technology to manufacture metal components and structures by welding sequential layers of metal.

The company was established in 2014, manufacturing medium to large scale commercial parts for the Mining, Oil & Gas, Defence, Marine and General Manufacturing sectors.

From its new head office and manufacturing space in Edinburgh Parks AML3D now provides commercial large-scale additive metal layering 3D printing services, using seven large format production cells for contract manufacturing of parts and components to a certified standard under an accredited Quality Management System.

Located in a shared facility, between a bus making factory and Brabham's Supercars assembly line in Adelaide's northern suburbs, AML3D houses seven state of the art WAM production cells in a 1,250m2 space. It is the only metals diversified large-scale WAM production plant in the Southern Hemisphere.

It became the world's first wire-feedstock additive manufacturing facility to receive qualification by Lloyd's Register, and is also compliant with the globally accepted American Welding Society standard specification for fabrication of metal components using additive manufacturing.

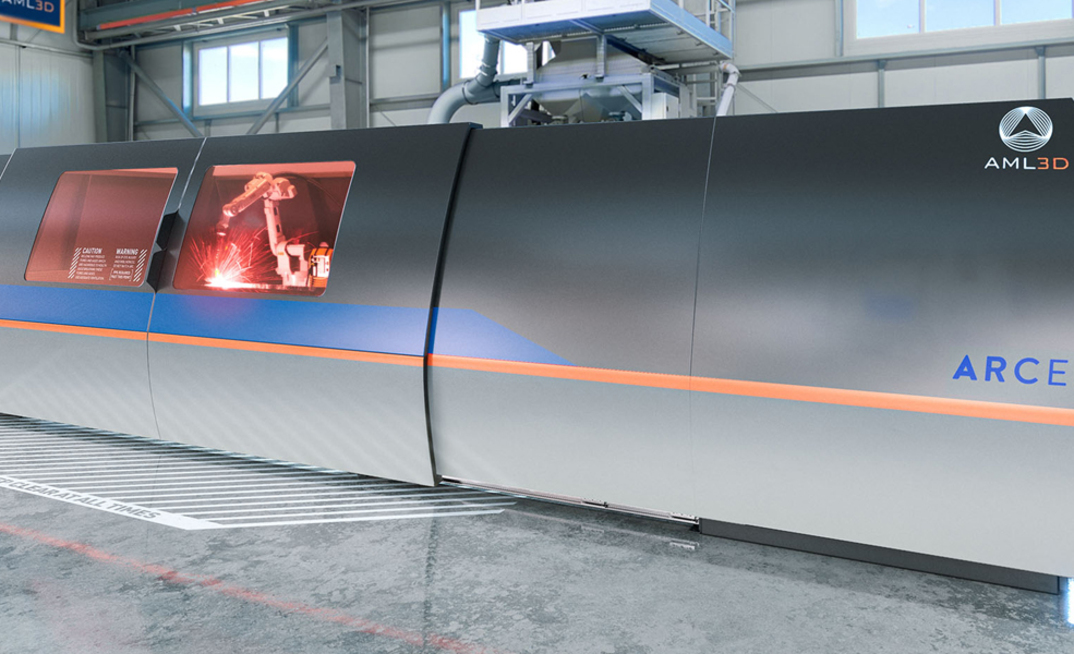

AML3D's facility is also home to two ARCEMY modules.

Driven by the company's WAMSoft proprietary software, ARCEMY is the world's first production-ready metal 3D printing module that allows users to create products on location from locally sourced materials.

AML3D Managing Director Andrew Sales said the lightbulb moment for the business came over a decade ago while he was studying at university in the United Kingdom, when he sat through a demonstration using arc welding techniques for 3D printing.

He said an old blacksmith-type process was used in a completely new and different way for manufacturing to replace chunky, casting, forging and big block machining components.

AML3D Managing Director Andrew Sales.

Sales realised after working in the Australian oil and gas industry it became obvious that traditional metal fabrication was not sustainable from a cost, efficiency and environmental perspective.

The $13.54 billion global metal fabrication market is dominated by metallurgical casting and forging.

However, traditional forging and casting takes considerable time and the supply chain is extensive and sometimes fraught with risk, with a large-scale industrial footprint needed to compete.

The antiquated and environmentally unfriendly processes also produce substantial waste and sizable emissions, with finished cast and forged products often lacking quality.

Sales said after a couple of years of research and development they came up with a cheaper, faster and more environmentally friendly approach to metal fabrication with the disruptive WAM 3D printing technology.

No different to the current 3D printers, WAM is delivered through a 3D platform.

The metal printing process works by first melting wire through plasma conveyed by an electric arc.

The WAM process then forms beads layer by layer to refine the metal geometry and turn out high specification metal components.

"There are numerous competitive advantages of ARCEMY, WAM and WAMSoft, but key is the ability to promptly deliver an array of high-quality, large-scale, custom built components to customers at competitive prices," Sales said.

"All of this can be done with significantly shorter lead times, less raw material input and waste and greater end product strength."

According to Sales, when compared with traditional fabrication processes WAM delivers cost savings of up to 70%, with the manufacturing process also 75% faster.

Waste is also reduced by up to 80%.

Sales said with such compelling statistics he believes WAM could become a driver of the fourth industrial revolution, with AML3D uniquely positioned as a leader in the fast-growing sector.

Independent, third party tests by National Association of Testing Laboratories accredited group Intertek Minerals comparing WAM's printed high strength steel components with more conventionally manufactured parts returned exceptional results in late-April, with the testing regime meeting all applicable global standards used in the defence, resource and automotive industries.

This testing showed the WAM process could potentially disrupt the flexible manufacturing space.

WAM manufactured products had 10% higher ultimate tensile strength than the same steel components made through conventional forging processes and 30% higher UTS than the global standard.

WAM is more effective for printing stronger, complex shapes than traditional fabrication methods and manufactured parts stronger than castings.

WAM can even make components that have become obsolete, which can minimise production downtime.

The process can be applied to all weldable metals and alloys to make components including turbine blades, manifolds, drill components, valves, connectors, pump and impeller components, pistons, tooling, pulleys, flanges, conveyor systems and chain links.

AML3D has successfully made high performance pump rings, an austenitic stainless steel mouthpiece and pistons for use in the mining, oil and gas industries.

For other industries the company has produced a Panama chock, a NAB propeller, Next Gen body armour and a fit for purpose Davit arm.

AML3D chairman Stephen Gerlach said in just a short period of time the company has become a global leader in the emerging large-scale 3D metal printing industry.

"Our technology combines welding science, robotics, metallurgy and software to produce automated wire fed 3D printing in a large freeform environment," he said.

"We firmly believe our technology will transform the metal manufacturing and fabrication landscape forever."

AML3D®, WAM®, WAMSoft®, AMLSoft® and ARCEMY® are all registered trademarks for AML3D Limited

ABOUT THIS COMPANY

AML3D

AML3D Limited was established to commercialise WAM® (Wire Additive Manufacturing) an emerging innovative metal additive manufacturing technology for the cost-effective production of large, high performance metal components and structures.

HEAD OFFICE:

- 35 Woomera Avenue, Edinburgh, South Australia, 5111, Australia

- Phone: +61 8 8258 2658

- Website: www.aml3d.com

- Email: trish.pollock@aml3d.com