Australian mining operators are one of the most efficient and resilient commodity producers on earth. As a trading nation the Australian brand signifies stability, quality, and consistency.

Since the 1980's, many industries, including manufacturing, have continued to embrace offshoring and just-in-time inventories to drive down costs and maintain their competitive position in the market. However, this supply methodology is a finely balanced act, as relative stability in trade relations and in transport infrastructure may have entrenched overconfidence in procurement, exposing a vulnerability that threatens to hang around for some time.

COVID-19 has fundamentally disrupted the global supply chain. The opportunity now for Australian mining companies and the supply and service communities that supports them is in collaboration, with the goal of reinstating confidence in the supply chain. This is not just a matter of auditing and planning, but also a matter of policy.

As an Australian manufacturer, McLanahan has experienced an increasing focus from our larger customers on low-cost procurement from increasingly specialised, centrally managed international supply organisations. Concurrently, the policy of reducing the number of suppliers in their supply chain data base narrows the supply pool for mining companies, with limited visibility towards second and third tier suppliers who feed the primary supplier.

Due to our connected world mining and mineral processing operations are now more complex, even more so in their supply chains. Until recently a dozer, a dump truck or a digger were mechanical machines, often manufactured and assembled in one or two locations. However, in 2021 this equipment is a complex combination of sensors, electronics, monitors and remote data management components, and each component has its own source of supply and route to market.

The most important tool in the supply chain is information. Diversification of suppliers to countries that have managed the COVID-19 outbreak well is one obvious way to reduce risk, accompanied by direct communication with that supplier and visibility of the sub-supplier network. The risk matrix is further strengthened by understanding the freight logistics of your supply network.

Local manufacturers within Australia provide lower risk supply options and reduce one layer of transport risk, but they often still require raw materials to be supplied from overseas or interstate sources. Regional manufacturing co-operatives or Australian Industry Capability Networks (AICN) are available for mining procurement teams to use to reduce the administrative burden in setting up and managing regional supply chains. During disruptions to supply many mining companies use another tactic, drawing on local relationships and manual processes to reduce the impact on their business. However, the COVID-19 disruption has proven to be a much more persistent, if not permanent disruption to supply chains and therefore this process needs to be formalised and integrated into the procurement system.

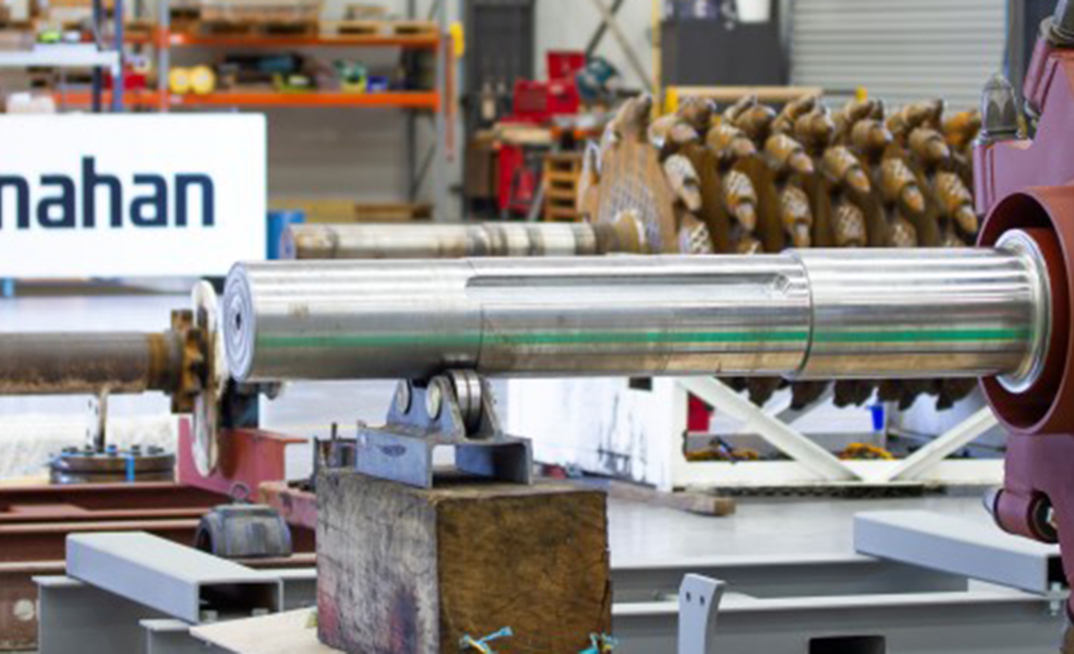

Part recycling, re-use, refurbishment, and upgrades are already part of the policy for a number of existing mining organisations. McLanahan engages with several mining companies who have strong policies prioritising the reduction of energy, transport, and their dependence on raw materials, who select refurbishing and upgrading their parts rather than replacing them with new. As an example, local manufacturers like McLanahan, will provide fabricated flywheels in place of cast flywheels, this reduces the amount of energy required during manufacture and for freight, and improves the ability to recycle the metal. In doing so the client's procurement team reduces risk, lead time, their carbon footprint, and delivers local support while aligning with the United Nations Sustainability Goal 12: Ensure sustainable consumption and production patterns.

Other factors also affect supply chain security. Nationalism, trade wars and global politics continue to influence the future of supply chain structures. Establishing a collaborative approach within our local industry with Key Performance Indicators (KPI) that included adaptability and resilience, will both maintain Australian industry know-how and deliver increasing confidence to Australia's international brand.

Connect with Chris

https://www.linkedin.com/in/knowlescj/

References

United Nations https://sdgs.un.org/goals/goal12

ABOUT THIS COMPANY

McLanahan Corporation

Feeding, Crushing, Sampling, Dewatering and Scrubbing equipment.

HEAD OFFICE:

- 27 Kalinya Close, Cameron Park, NSW 2285, Australia

- Phone: +61 2 4924 8248

- Website: www.mclanahan.com.au

- Email: sales@mclanahan.com.au