The humble slurry pump plays a vital role in the harsh mining landscape. Ensuring pump longevity has historically been a challenge, yet a failure can directly impact output and productivity.

Thankfully, advanced technology now offers multiple solutions to help extend the active life of slurry pumps, from seals to lubricants, packing and right through to innovative monitoring solutions. And with industry competition becoming ever fiercer, paying close attention to the health of an operation's slurry pump isn't just a nice-to-do; it's an essential requirement for any successful operation.

Slurry Pumps: The challenges

In many cases, slurry pumps work continually in hostile environments. This leads to particularly difficult maintenance due to some, or all, of the following:

- Operating 24/7/365.

- Bearings are continually subjected to vibration.

- Corrosive chemicals, abrasive substances and moisture continually contaminate the bearings and seals.

- The provision of adequate greasing is complex. It usually requires pumps' shutdown on a regular basis (as often as every few weeks).

- The risk of over or under-greasing is high. This leads to excessive heat build-up and premature bearing failure.

- Internal elements of the pump become worn by abrasive materials moving through, leading to reduced pump longevity.

The overriding issue with the correct working of a slurry pump or sealing system is the difficulty of effective monitoring. If you don't have real-time data of vibration, temperature and pressure, then putting a wholly effective maintenance program in place relies more on guesswork than a scientific process.

Slurry Pumps: The solution

Successfully extending the working life of a slurry pump requires a three-pronged approach that addresses the following:

- Effective monitoring

- The right mechanical packing, seals and lubrication

- Protecting the internal workings of the pump

The right solution can dramatically extend the working life of a slurry pump and reduce the need for costly maintenance shutdowns. Sealing experts Chesterton has brought innovative solutions to market designed to be used in both isolation and combination to create a powerful solution to each challenge.

1. Effective monitoring with Chesterton Connect

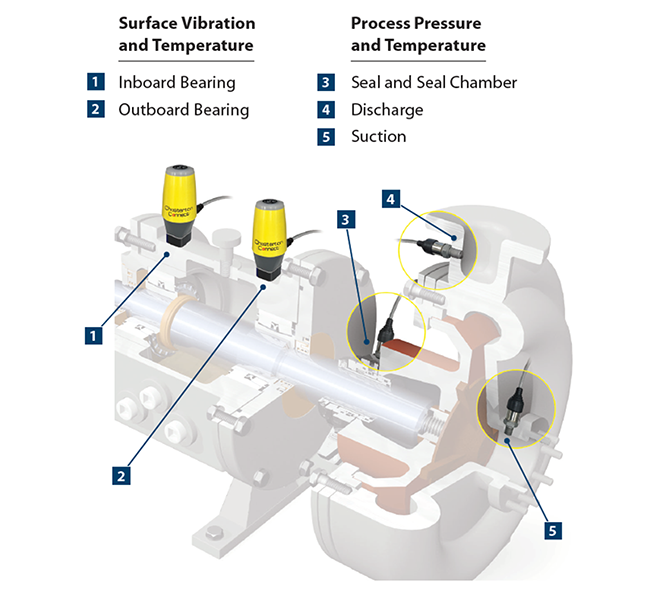

Imagine a device that could monitor equipment process and operating conditions. Now imagine that it could do so remotely and in harsh conditions. Finally, imagine the ability to connect to multiple sensors, receive alerts, and monitor the data via a simple app.

This is not a figment of imagination, nor is it a prototype. This is a proven and new-to-market product known as Chesterton Connect - simplified equipment and process monitoring unit for pumps and sealing systems.

Not only is it easy to install, but this data acquisition tool allows users to accurately monitor vibrations, surface temperature, process temperature and process pressure. Using Bluetooth technology, undesirable events can be far better understood, leading to effective maintenance and preventative actions to extend longevity.

Once we understand that slurry pump failure is almost always down to a lack of knowledge about the pump's health and working conditions, the effective provision of the other two aspects becomes easier to manage.

2. The right lubrication, mechanical packaging and seals

The choice of grease is an essential element of slurry pump longevity. Ensuring that it can cope with extreme pressure and the corrosive elements associated with slurry is essential. Chesterton has designed a range of greases that provide outstanding performance in various conditions, including the Chesterton 635 SXC and the Chesterton 630 SXCF, both of which provide exceptional lubrication capabilities.

However, applying good grease at the right amount at the right time has always been a challenge. Enter the Chesterton Lubri-Cup, an automatic lubricant dispenser that applies exactly the correct amount at bespoke intervals. This innovative solution has been pivotal in solving many unnecessary slurry pump failures. Indeed, such is its success that the Lubri-Cup/Chesterton Grease combination has effectively extended slurry pump lifespan by over 100%, as shown in this case study.

When it comes to mechanical packing and mechanical seals, the key to slurry pump health is to eliminate expensive external seal flushes and withstand the harsh environment. The Chesterton 170L Slurry Cartridge Single Seal combined with their trademarked SpiralTrac mechanical packaging has created an outstanding solution. Whether used in isolation or combination with any of the above slurry pump measures, these environment-specific seal remedies have provided a revolutionary way to improve slurry pump performance.

3. Protecting the internal workings of the pump

Of course, we can't ignore the corrosive effect that slurry has on the internal workings of the pump. Chesterton's ingenious ARC MX1 coating has been formulated to dramatically negate the effect of dry, coarse particle erosion and sliding wear abrasion.

Slurry pumps are one of the most critical components within the mining industry. For too long, there hasn't been defined and strategic solutions to ensure their health and longevity. It seems that now, at last, this may well be a thing of the past.

Find out more at www.chestertonrotating.chesterton.com

https://www.chestertoncustomseal.com.au/partners-chesterton-products/

ABOUT THIS COMPANY

Chesterton

Stress, high impact, slurries, dust and dirt, corrosion, and lack of water can all have an enormous impact on mining equipment reliability and uptime. For decades, Chesterton specialists have helped mining operations around the globe meet these challenges with expertise and advanced solutions in sealing, lubrication, and protective coatings.

Chesterton Customseal is a joint venture between A.W. Chesterton Company and Customseal Australia. Chesterton Customseal provides our clients with innovative solutions in high-performance seals, combining the strong capabilities of two brands in one product.

CHESTERTON ASIA PACIFIC:

All Chesterton Products Distributors Channel

Chesterton Website - chesterton.com

CHESTERTON CUSTOMSEAL:

Chesterton Customseal’s industry-proven sealing solutions deliver the highest value by extending the hours of your operation between maintenance intervals of your equipment and increasing overall asset life. We provide sealing solutions as well as replacement kits for refurbished equipment.

Chesterton Customseal website - chestertoncustomseal.com.au

Chesterton Customseal address: 95 Excellence Drive, Wangara WA 6065

Contact us