The shift from diesel to battery-powered vehicles in underground mining has already begun, but a wider rollout is not without challenges - especially from a safety perspective.

Major advantages of using battery-electric vehicles (BEVs) underground include the absence of carcinogenic emissions and a reduced heat signature. While this all but guarantees an improved operating environment, current safety monitoring and shut-down systems are designed for diesel vehicles and therefore must be adapted to fit their battery-powered replacements. Enter Nautitech, a Sydney-based original technology manufacturer (OTM) that has seen the transition to BEVs coming and has been working on harnessing technology to keep miners safe in all underground conditions. Their technical solutions are agnostic of vehicle type; they work with diesel, battery or electric. This allows miners and OEMs to swap the technology across with minimal fuss.

"The revolution doesn't have to be a shock; it can just be a shift. From a technological perspective, the same principles apply to monitoring and shutdown systems on a diesel vs. battery powered vehicle," said Mac Powolny, Nautitech NAUTITECH ENABLING SAFE OPERATION OF BEVS UNDERGROUND UNDERGROUND MINING AND THE CHARGE TOWARDS ZERO-EMISSIONS FLEETS NAUTITECH Aussie firm is ahead of the pack on technological solutions for battery-powered mining vehicles for hazardous zones 13 UNDERGROUND MINING AND THE CHARGE TOWARDS ZERO-EMISSIONS FLEETS CEO. "It's a simple swap of the air solenoid to a relay to make the technology compatible with battery vehicles. What it means is, if the mine site has been using our technology for a while, they don't have to change out everything. Our user interface can facilitate a quick transition," he added.

Nautitech has already supplied its Methane Master shut-down systems to LDO Group, the Australian distributor of Rokion electric vehicles, as well as to the BHP Mitsubishi Alliance in the Bowen Basin of Central Queensland via Canada's Miller Technology. They also work closely with 3ME, an Australian heavy vehicle battery manufacturer.

Powolny believes while the number of vehicles will remain the same regardless of electrification, demand for monitoring systems will increase to ensure there are no hiccups with the nascent technology.

"There is a huge concern in the industry about what may happen if a battery powered machine catches fire underground - it would be an event likened to Fukushima and would send shockwaves through the industry.

"Of course, we don't want that to happen, and being in the electronic space, Nautitech can provide technology to monitor the temperature of EV batteries and send a signal that allows mining companies to take relevant action such as fire suppression," said Powolny.

Nautitech has made a name for itself as an Aussie-owned and operated OTM. It invests 15% of its turnover in R&D, and it does everything in-house with its own team of about 10 engineers who are dedicated exclusively to smart electronic solutions for OEMs and underground mining companies.

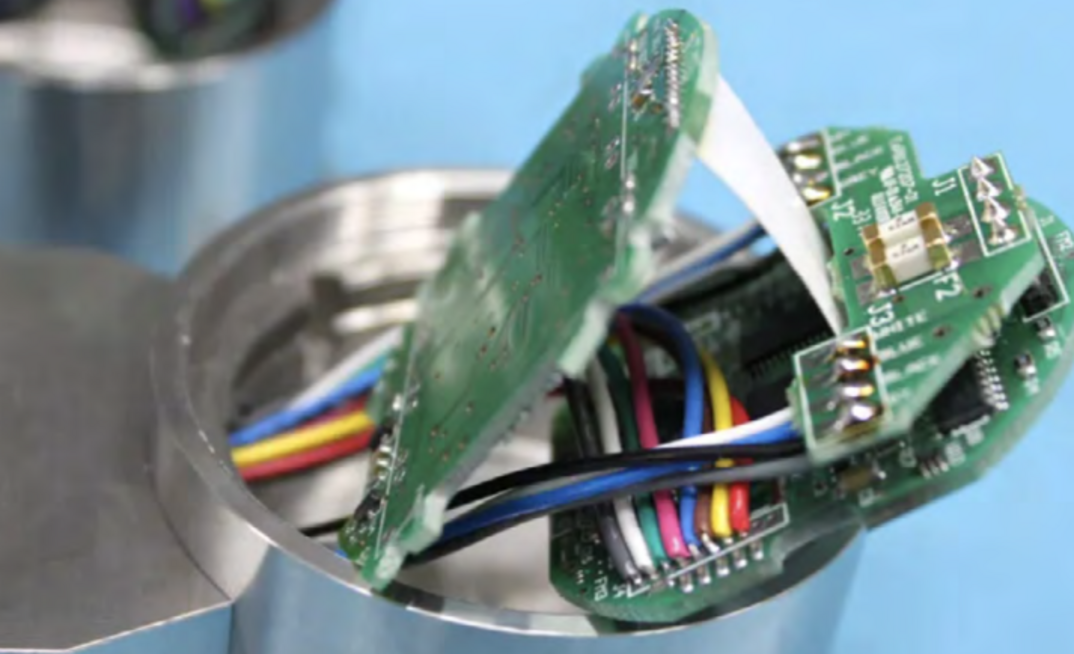

Founded just over 20 years ago and focusing exclusively on the soft-rock space, success came first via the company's Methane Master CH4 monitoring and shutdown systems, before its expansion into technology in the connectivity area. One of the company's main functions now is as a provider of broadband powerline modem (BPLM) technology, allowing operators to control electrical machinery deployed deep underground.

"Some of the networking solutions for underground mining just don't work one UNDERGROUND MINING AND THE CHARGE TOWARDS ZERO-EMISSIONS FLEETS NAUTITECH UNDERGROUND MINING AND THE CHARGE TOWARDS ZERO-EMISSIONS FLEETS 14 kilometre underground - because of challenging infrastructure, confined spaces, the environment, hazardous areas, roof falls, even the amount of steel that is used on the equipment," said Powolny. "With our Spitfire BPLM technology, mines can immediately achieve connectivity with underground mining machinery through the trailing cables.

The technology is pretty neat because you don't have to daisy chain with Wi-Fi access points or rely on fibre connectivity, which is very fragile in the underground mining environment.

Other products Nautitech is focusing on include its CUBEx Intrinsically Safe (I.S.) lighting solutions, which are vital in an environment where an errant spark from a smashed bulb could ignite a flammable gas or dust cloud. The company's developments in this area have become an industry benchmark, offering best in class performance.

"We are being run off our feet trying to keep up with the demand for our CUBEx I.S. lights," said David McCloskey, business development manager at Nautitech.

"They're being fitted on just about every piece of underground mining equipment you can think of. We now have a large OEM that's fitting them as standard equipment on their shuttle cars at their customer's request, so that's a big thrust for us going forward," he added.

Another new product is the Hawkeye Quad 7-inch smart display mounted on machines to visualise what's being picked up by thermal cameras, which are able to see through dust, water sprays and mist as if these conditions are not there.

"It's great for mining vehicles, particularly shuttle cars when they're coming up to the back of a continuous miner and there are clouds of dust causing poor visibility. With the view from a thermal camera via the Hawkeye Quad, you can clearly see if there is anyone in close proximity and if it's safe to drive forward," said McCloskey.

The 7-inch display also allows the user to record images it receives, acting as a dash cam that can be recovered in case of an accident, much like a black box in an airplane. As befits any futurefacing company, Nautitech is positioning itself as a modern employer and champion of diversity.

"We are ticking all the boxes, not only decarbonisation, but most of the boxes related to the United Nations Sustainability Goals.

We pride ourselves to be a very inclusive company, with 40% of our female staff in management positions, a team that consists of 11 nationalities with 14 spoken languages, and probably about 20 different accents, including mine!" said Powolny. While the company's business is based on organic growth, one of its main strengths, according to Powolny, is agility. We have a quick decision-making process so we can react and pivot when we need to, ultimately benefiting our customers," he said.

ABOUT THIS COMPANY

Nautitech

Nautitech is a high-tech engineering company and manufacturer specialising in EX d and Intrinsically Safe equipment that improves safety and productivity in hazardous areas. We are the largest supplier of underground Methane Shutdown and Broadband Communications systems in Australia. Our Lights, Displays, HD and Thermal Cameras add an important visual element for monitoring complex underground spaces.

Head Office

- Address: 3/9 Packard Avenue, Castle Hill NSW 2154

- Phone number: +61 2 9899 6857

- Email: sales@nautitech.com.au