One of the mining industry's biggest challenges is the significant waste generated by used equipment and machinery. Murray Engineering, a leader in mining services, is addressing this issue head-on with innovative solutions focusing on sustainability.

The mining industry worldwide is grappling with its environmental impact, accounting for 2%–3% of global carbon emissions. Adopting more sustainable practices has become vital. Embracing circular economy principles — which focus on reusing, refurbishing and recycling materials — can help it to achieve this.

The shift to green energy demands an unprecedented level of effort from the mining industry to meet the global need for raw materials, particularly minerals and metals. This challenge presents a significant opportunity, but emphasis must at the same time be placed on the importance of extending equipment lifecycles and minimising waste.

Murray Engineering's comprehensive rebuild and repair services can help the industry fulfil these goals. Established in Kalgoorlie, Western Australia in 2006, the company provides a wide range of second-hand and refurbished underground hard rock mining equipment, including drills, loaders, dump trucks, integrated tool carriers, agitator trucks, light vehicles and ancillary kits as part of its circular service offerings tailored to sustainable operations.

Murray's rebuild services are designed to meet the specific needs of each client, whether it involves a full zero hour, mid-life rebuild or a quick refurbishment before deployment to a new site. This process involves a thorough restoration of equipment to its original factory specifications, effectively returning it to a 'like-new' condition.

"To keep up to date with the underground mining technology cycle, machines should be less than ten years old." says Nathan Bradshaw, key account manager at Murray Engineering. "We are not rebuilding a 20-year-old piece of equipment; often it's less than five years old to stay ahead of the cycle. It's essential that we take end-of-first-life machines and, instead of sending them to waste, we refurbish them. This gives the machine another 5 plus years in the technology cycle and postpones their journey to landfill."

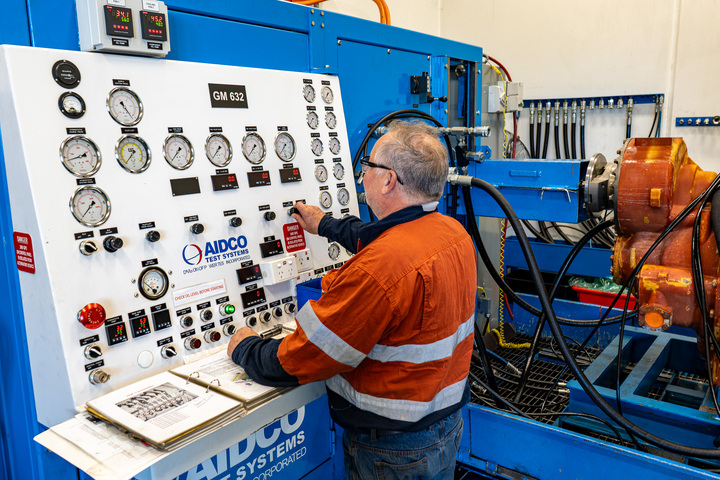

Murray Engineering also provides custom fit-outs for a wide range of mobile machines and fixed-plant equipment, ensuring peak performance and safety for mining operations. Furthermore, it offers a service exchange components programme to further support a circular, sustainable way of mining.

Cost-effective maintenance solutions

Murray also offers several maintenance and repair contract (MARC) solutions for its customers. Under MARC, it maintains the equipment to ensure it remains operational and prevents breakdowns. It handles repairs, maintenance and diagnosis for faults as they arise. Its MARC services operate under a service meter unit (SMU) rates system. The costs associated with maintaining and repairing equipment are based on the SMU readings and key performance indicators set by the customer in the contract.

Under MARC, it provides on-site support and a plant management system. Digital scheduling and maintenance reporting lead to streamlined client interactions.

A major issue for many mining companies is the cost of new equipment and the timescale to obtain it. For example, a new mine start-up or a care and maintenance mine coming back into production will require trucks, loaders, drills, ancillary equipment, light vehicles, pumps and electrical equipment.

"It will need all that on day one," says Bradshaw. "The cost is exorbitant. Equipment can also be hard to obtain. If you're placing an order now, you're looking at a 30- to 60-week lead time on some equipment. Murray Engineering has access to a wide range of second-hand, used equipment suitable for rebuild in a more responsive time frame.

"We deploy our capital to buy a machine and rebuild it. We then hire it to the customer to operate on a monthly hire basis. They operate it but we maintain it through its lifecycle. In cost terms, it gives the mine owners a very low entry point to begin a mine or restart one without the headache of maintenance."

With 13 years of maintenance experience under the MARC service model, Murray Engineering supplies equipment to mines of all sizes, including some of Australia's largest sites. It has supported large-scale projects across Western Australia, South Australia and Queensland, and established itself as a key service provider to mining companies in the country.

Mining talent shortages

One of the other biggest challenges the mining industry faces is a shortage of skilled labour. The Australian economy is facing the worst skills and labour shortages in a generation, according to the Minerals Council of Australia. Many mining companies report that it is harder to recruit and retain talent than a few years ago. Mining leaders say the talent shortage stops them from delivering on production targets and strategic objectives.

"Skilled labour supply is a big issue in the mining industry," adds Bradshaw. "Murray Engineering's systems and processes have been built up with over 30 years of underground mining experience, supplying customers worldwide. By engaging with us, clients get 30 years of experience in maintenance and procurement.

"Many sites in Australia are using a brand-new kit or starting from scratch. They have hired new staff and are trying to mine at the same time. They have a steep learning curve and cannot focus on the mining aspect. But we can assist by providing the equipment, systems, processes and support so that the company can concentrate on mining.

"Our staff are very experienced and seasoned. In turn, they are training new people just starting in the industry and passing on their skills and knowledge. Our people are our most valuable asset when it comes to providing the quality services our clients have come to expect from us."

Headquartered in a state-of-the-art 55,000 sq m workshop complex in Western Australia, Murray Engineering employs around 500 people, 85% of whom are engineers and tradespeople. Its well-trained workforce enables it to maintain its high standards in equipment refurbishment and maintenance.

As the mining industry pivots towards adopting more sustainable practices, embracing circular economy principles is becoming the new norm. Murray Engineering's focus on these principles is a guiding example of how the sector can reduce waste, lower costs and extend the lifecycle of machinery. By combining decades of expertise with a commitment to sustainability, it is helping to pave the way for a more sustainable future in mining.

ABOUT THIS COMPANY

Murray Engineering

Contact:

Murray Engineering

54 Munday Avenue, Pinjarra

Western Australia 6208

Ph: +61 8 9550 5800

Email: info@murrayengineering.com.au

Web: www.murrayengineering.com.au

Murray Mining Services Mongolia LLC

Unit 303, City Center

Altangerel Street, 8th Khoroo

Sukhbaatar district

Ulaanbaatar-14200, Mongolia

Ph: +976-94059010/+976-99094814

Email: info@murrays.mn