Mining is a major pillar of Australia's economy. As the industry looks towards the future, sustainable mining practices have emerged as a critical focus area. This article explores the evolving landscape of mining in Australia, with a particular emphasis on sustainability, the use of alternate fuels, and the role of ABB technology in driving the transformation towards a more sustainable mining industry.

Electrifying mines requires huge investments, more electricity and better infrastructure. Mines need to connect to the grid, build substations, and use renewable power. There is technology to support, and the benefits outweigh the challenges in the longer term:

- Better operational performance

- Lower operating costs

- Battery technology advancements

- Achieve CO2 emission reduction targets

Electric equipment could enable steeper ramps, lower waste removal, quicker cycles and fewer breakdowns. The latest batteries are more efficient, cheaper, faster charging and larger to compete with conventional equipment.

ABB's energy-efficient traction converter and energy storage systems (ESS) are helping mining companies transition towards low-carbon emission solutions. This is achieved through an efficient and flexible traction system, which switches off the diesel engine in the railway station without affecting the lighting and air conditioning. When integrated with flexible traction converters, the battery technology enables a further energy efficiency upgrade.

In diesel-battery applications, onboard energy storage helps to reduce harmful local emissions. This is because the stored energy can be used to feed auxiliary loads when the vehicle is approaching and dwelling at stations. The vehicle can also accelerate away from a station by using energy stored in the battery instead of operating the diesel engine. ABB's reliable and safe ESS ensures the battery lasts long and can handle high-power charging and frequent charge-discharge cycles.

Further electrification could cut energy expenses and reduce maintenance costs for mobile equipment, lowering OPEX year-on-year. A fully electric mine powered by renewables could shrink its carbon footprint significantly, avoiding carbon taxes and capturing potential green-product premiums.

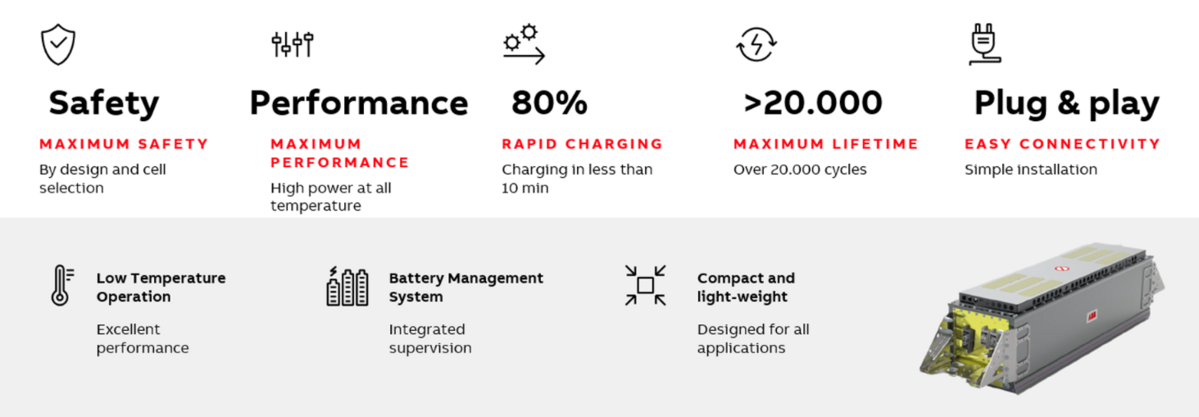

Harnessing alternate fuels for sustainable mining:Mining companies use renewable energy and batteries to lower emissions and costs. Transportation is a major source of energy use and carbon emissions. Braking wastes energy as heat. Traction converters and electric motors can recapture this energy and deliver it back into the battery. For example, ABB's Borderline ESS batteries are based on LTO technology, guaranteeing safety, rapid charging-discharging and a long lifespan.

Features of ABB's Borderline ESS

Mining and construction vehicles demand a high-power charge and discharge cycle, vibration and operating temperature. For example, when we collaborated with First Mode to retrofit diesel electric-driven heavy haul 220+ tonnes capacity trucks with a fuel-cell solution, the LTO batteries were the most suitable option for hydrogen application.

First Mode's fleet of zero-emission haulage trucks that will be using ABB BORDLINE® lithium-ion energy storage systems.

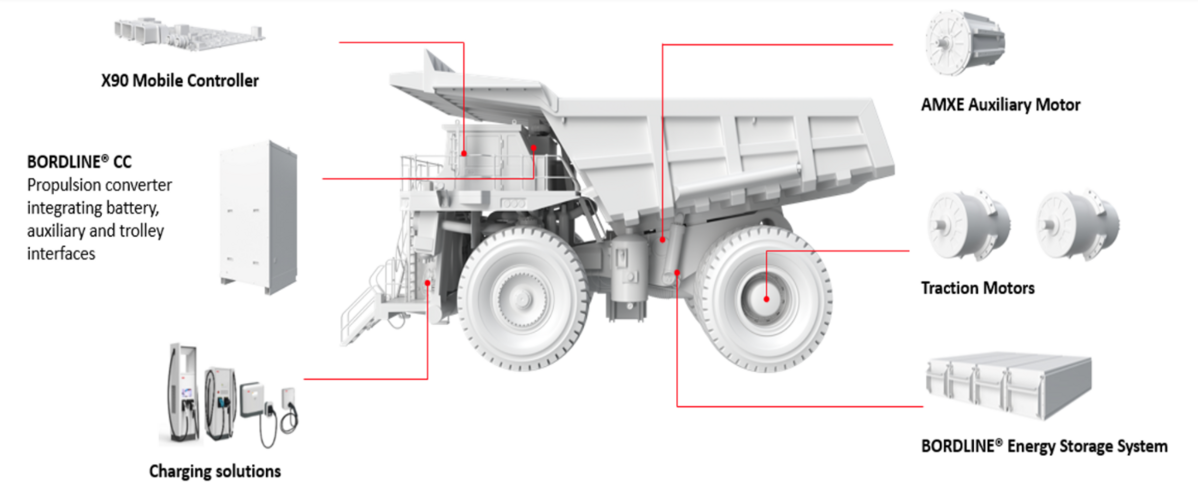

ABB collaborated with Hitachi Machinery to supply an ESS and MW range DC/DC converter to develop Trolly Hybrid 180 tonnes capacity Mining Trucks. This showcases the maturity of today's battery technology for enabling a mining truck to run purely on battery and with increased efficiency. ABB also provides charging solutions designed to interface with all vehicles, supporting an interoperable approach based on proven standards that can provide any solution needed to charge BEVs.

ABB products for Mining Truck electrification

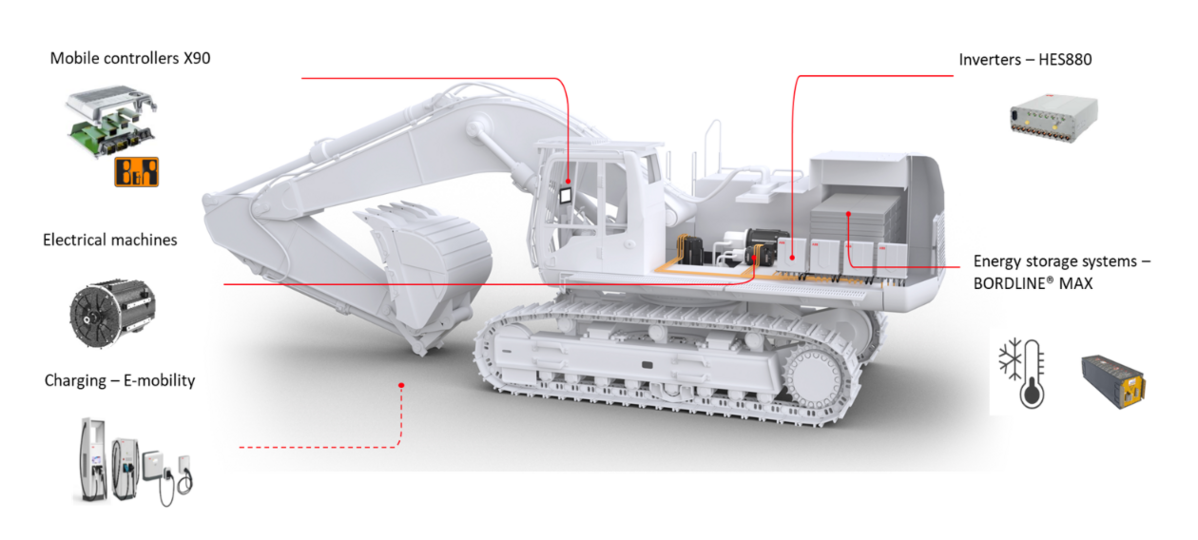

ABB products for heavy construction equipment electrification

The grinding mill

Another crucial area to focus on is the grinding mill, as this equipment has the most significant impact on the performance and sustainability of mining operations and is responsible for up to 40% of a mining facility's total energy usage. Utilising well-established technology, such as variable speed drives (VSDs) paired with high-efficiency electric motors, can optimise productivity and ensure availability while reducing energy consumption.

ABB's technology has been instrumental in making mining operations more sustainable. With a focus on responsible mining practices, the use of alternate fuels, and the adoption of cutting-edge technologies, mining companies can minimise their environmental impact. ABB's advanced technology solutions are crucial in driving this transformation, enabling mining operations to become more efficient, safer and environmentally friendly. As the future unfolds, the collaboration between mining companies and technology providers like ABB will continue to shape a sustainable mining industry in Australia and contribute to a greener planet.

ABB will be at Future of Mining Perth on September 18-19, come visit them at stand 5.

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company's solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated.

ABOUT THIS COMPANY

ABB

ABB is a market leader in mine digitalisation, mine automation, electrification and mine hoists. Companies of all sizes around the globe trust ABB to be their digital transformation partner. We are transforming the way mines operate, creating a digitally enabled environment that is safe, clean and sustainable, with a workforce carrying out exciting, stimulating tasks.

HEAD OFFICE:

- Bapaume Road, Moorebank, NSW, 2170, Australia

- Phone: 1800222435

- Website: new.abb.com/mining

- Email: australia.marketing@au.abb.com