Published in June 2007 Australian Longwall Magazine

Angus Place technical services manager Peter Corbett said during development drivage in geologically disturbed areas of the mine, roof guttering and cavities formed at the face and then tended to increase in height and width until they were unable to be supported by the bolting rigs on the continuous miner. In the past, hand-held roof bolters operated out of a QDS work platform were used to support the roof in the cavity areas.

The Wolgan Zone is the major geological zone in the current mining area and runs across all of the Southern Area longwall blocks at Angus Place and extends into the adjoining Springvale lease. The Wolgan Zone has extensive geological faulting and a broad zone of high horizontal stress conditions (about 300m wide).

Longwall continuity at the mine has been hampered by slow development drivage in the Wolgan Zone, costing mine owner Centennial Coal several weeks of lost longwall production in the last two longwall blocks. During development of the previous two sets of gateroads, roof guttering and cavities formed at the face which were 1–2m above the normal roof horizon. Poor floor conditions also hampered development throughout the zone.

A major initiative was launched by the mine at the start of 2006 to find ways to improve the development process in geologically structured areas, with a strong focus on risk reduction.

“One of the main concepts we wanted to develop was a way of ‘spiling’ from the continuous miner at the development face. Spiling is a process where bolts are installed horizontally into the face at close centres to form a protective ‘canopy’ under which to continue development drivage,” Corbett said.

Angus Place representatives discussed the issue with other industry suppliers without success before approaching Rambor in April 2006.

A team made up of mine operators, tradesmen, deputies and senior mine management was formed to work with Rambor to develop a new process and machine to overcome the strata support issues.

There were three key innovations devised by the team to improve the development mining process in the Wolgan Zone:

*Shield Tilt: fitted to the continuous miner to allow roof bolting rigs to be tilted towards the face to allow roof bolts to be installed closer to the face;

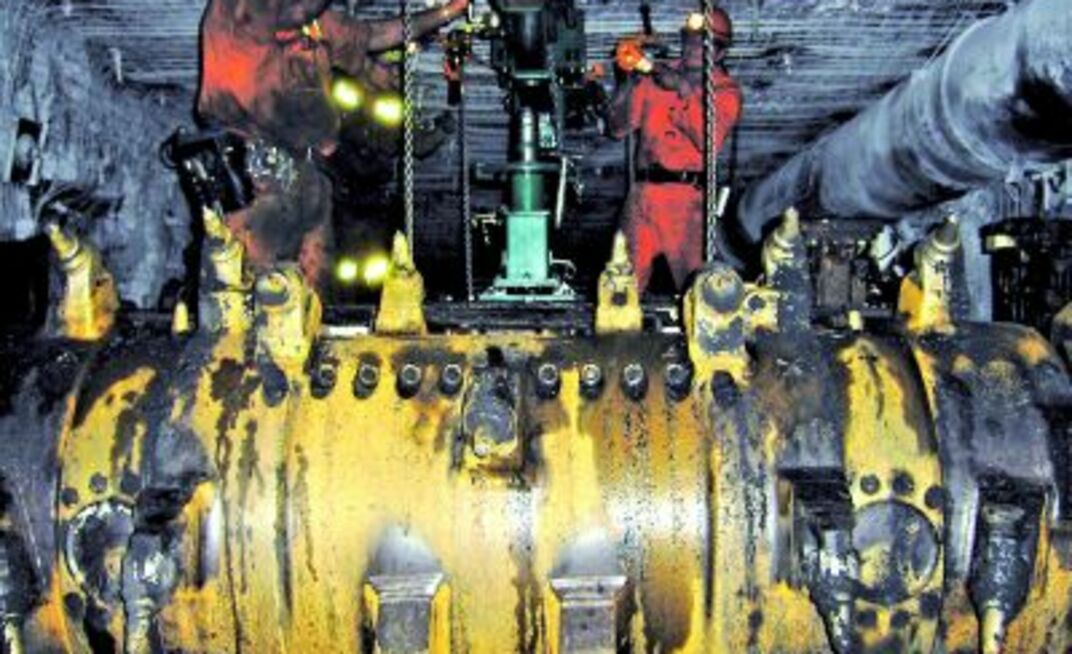

*Miner Mounted Spiling Rig: adapted to the head frame of the miner to allow spiling of the face with horizontal bolts where cavities formed at the face; and

*Wolgan Zone Process Plan: a detailed plan of the mining/support cycle was devised to implement the changes from normal mining process.

“The idea was to drill and install 2.5m bolts at 300mm centres across the heading at a five-degree angle above the horizontal into the face at the normal roof level,” Corbett said.

“This would then break the cycle of cavity propagation and stabilise the roof in the spiled area. The continuous miner would then be able to continue the development cycle with minimum disruption to the development drivage process.”

Throughout the design and manufacture process, Rambor presented the Angus Place team with 3D design drawings and made modifications to the machine to incorporate their ideas. “Before we encountered the Wolgan Zone, concept designs were produced, risk assessments were carried out, all stakeholders were approached and their comments noted, and finally a continuous miner mounted spiling rig was manufactured,” Corbett said.

After some minor modifications and operator familiarisation, the spiling rig consistently installed a full round of 20 Hilti self-drilling roof bolts in a single eight-hour shift (including mounting and dismounting of the rig from the CM), with only two operators. In the past, cavity support and spiling operations averaged nearly seven shifts per round.

“For the first time at Angus Place we were able to mine through the Wolgan Zone without additional hand-held roof bolting of cavities – a major improvement for the development process at the mine,” Corbett said. “We spiled the face on six occasions in the Wolgan Zone in 940 Panel, with each round achieving the goal of breaking the cycle of cavity propagation and returning the roof to the normal horizon.”

The exercise also resulted in another first for the industry, with the spiling rig able to install Hilti self-drilling bolts. “The use of the Hilti self-drilling bolts not only enhanced the operational efficiency but the safety of the spiling process as well, as all operations were conducted at a safe distance from the face and under supported roof,” Corbett said.