After working with mines from around the world for over 25 years, we've heard quite a few concerns - and misperceptions - about predictive maintenance. To help you understand the truth about predictive maintenance, we've addressed four of the top myths in this article.

Myth #1: "We can't even do basic maintenance well, so there's no way that we can do predictive maintenance."

Implementing predictive maintenance isn't predicated on doing traditional preventive maintenance well - or even at all. DINGO's goal is to shoulder all the heavy lifting and maximize your current processes, so your team can focus on its tasks while we implement predictive maintenance for you.

Routine maintenance is usually triggered by breakdowns and fixed factors like time, age, service recommendations, and meter readings. The downside to preventative maintenance is that it's easy to miss something if it occurs outside the scheduled maintenance window. Conversely, predictive maintenance is based on the actual operating condition of your equipment, so it's continually assessing if everything is functioning well.

DINGO's asset health software, Trakka®, captures predictive health information automatically from each of your machines, reports on performance, and if problems are found, schedules a service request in advance to prevent equipment failures. We maximize the data you already have - including preventive maintenance data − so an issue can be addressed before it becomes a problem.

"Less than 1% of available data in the mining industry is being used.

By unlocking the value of this dormant data, the industry could save $100 billion in cumulative maintenance costs by 2025." - McKinsey & Company

Myth #2: "We already tried something like predictive maintenance, and it doesn't work."

There are different approaches to predictive maintenance and, honestly, many don't work well. Some mines rely on sensor data to understand which equipment needs attention. The downside is that sensor data is only part of the story - according to Dingo's maintenance experts, over 80% of all problems are found via other condition monitoring sources.

Another challenge is that the amount of data gathered is often overwhelming and nearly impossible to analyze manually. On average, less than 1% of available data in the mining industry is being used - if that data was being intelligently utilized, it could prevent costly and time-consuming equipment breakdowns. (1)

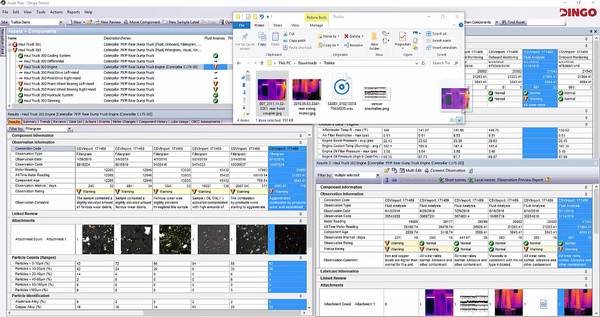

DINGO's Trakka 4.5 ingests, curates, and analyzes data from almost any source while recommending actions to remediate issues. By using predictive analysis and machine learning, Trakka can ‘learn' from patterns and make intelligent predictions based on the data.

TRAKKA predictive maintenance software makes it easy to analyze all condition data, including images and documents, in one centralized platform to improve insights, corrective actions and outcomes.

DINGO also believes that data analysis alone isn't enough - human expertise also needs to be applied to troubleshoot and diagnose issues. Our team of Condition Intelligence experts has over 800 years of combined maintenance experience and manages the condition of over 150,000 vital components. They'll review your condition monitoring data daily to proactively identify issues and recommend corrective actions. They will also continue to monitor open issues until your equipment returns to a normal operating state.

Myth #3: "We're already doing well enough."

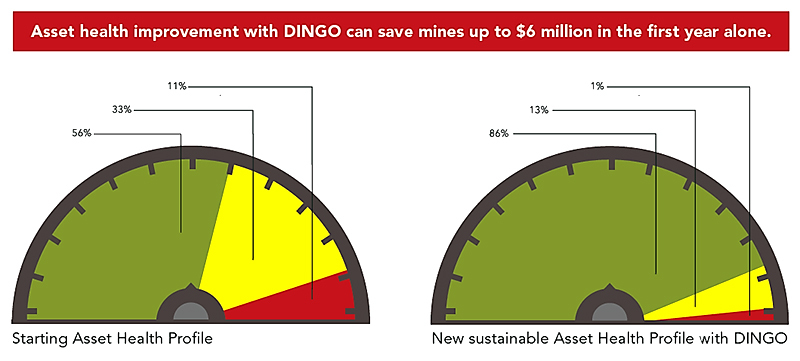

We've found that most mines don't realize just how well they could perform if they had the right technology in place. Nearly every mine has room for improvement: based on data compiled from more than 50 mining operations across the globe, 33% of major components are regularly operating in a warning state and more than 11% are running in critical condition. (2)

Inside each of your machines is a wealth of information. Predictive maintenance and asset health software is about listening, searching, locating, and acting to fix impending issues before they become major problems.

"Our mine has had the DINGO system in place since 2009, and the results have been remarkable.

Dingo has identified many preventable issues that we would never have been aware of until it was too late." - Reliability Engineer

A good example is a small surface mine we worked with in Nevada. They wanted to reduce their maintenance budget by 15%. By monitoring their equipment through Trakka, we reduced that target by 24% in the first year. This isn't unusual: on average, DINGO customers achieve a 4:1 ROI on parts alone.

DINGO has helped hundreds of mining companies so we have extensive real-world experience in what constitutes doing "well enough." We've compiled the world's largest set of performance data on mining equipment components; this information is based on real-world operating data so it gives an accurate picture of your equipment's performance. We can use this data to help you benchmark your mine's current performance and define reasonable objectives for improvement.

Myth #4: "A predictive maintenance system will make me look bad."

Actually, our objective is to make you look good and become your trusted advisor. We function as a partner in giving you the tools your mine needs to increase availability, extend component life, and reduce maintenance costs, so you get the credit and the pat on the back.

We understand you need a quick win, so our programs are geared towards bringing your overall fleet condition to an ideal health state within the first three months. The typical payback with DINGO is greater than 4 to 1 with in 12 months.

Figure 1: A real-world return in one year from using DINGO à $6 million saved due to asset health improvement.

A mining customer had this to say about how DINGO helped him achieve his goals,

"With Trakka, I can understand, manage, and reduce the cost for every run hour on a piece of equipment. Having all of our condition data in one place also helps manage risk. By understanding my level of risk, I can do a better job of managing my budget and stretching things out with confidence."

For more real-world feedback from our mining customers, read through our case studies.

Next Steps

Don't let misperceptions about predictive maintenance hold your mine back from implementing a world-class asset health program. By blending predictive maintenance technology with human expertise, DINGO can help your mine realize increased availability while extending component life and reducing operating costs.

Contact us today to find out how your mine can quickly and cost-effectively implement an industry-leading predictive maintenance program that will reduce your maintenance costs by millions.

(1) The Healthy Digital Mine, Dingo.

(2) Small Steps to Big Results, World Coal, January 2016.

ABOUT THIS COMPANY

Dingo

HEAD OFFICE:

- 16 Macgregor Street, Wilston QLD 4051 Australia

- Phone: +61 7 3115 9000

- Website: www.dingo.com

- Email: info@dingo.com