The focus for reducing global fossil fuel emissions for the last decade has been on alternative energy technology. Hydrogen is most likely to present the next challenge to coal mining, this time in the production of iron and steel. Countries with large steel production certainly feel pressure to act in a more aggressive manner in order to comply with the Paris Agreement and reach zero emissions by 2060 and beyond. This drastic reduction can only be achieved with fundamental process and technological changes. For the steel industry, one proposed alternative is to replace coking coal with hydrogen.

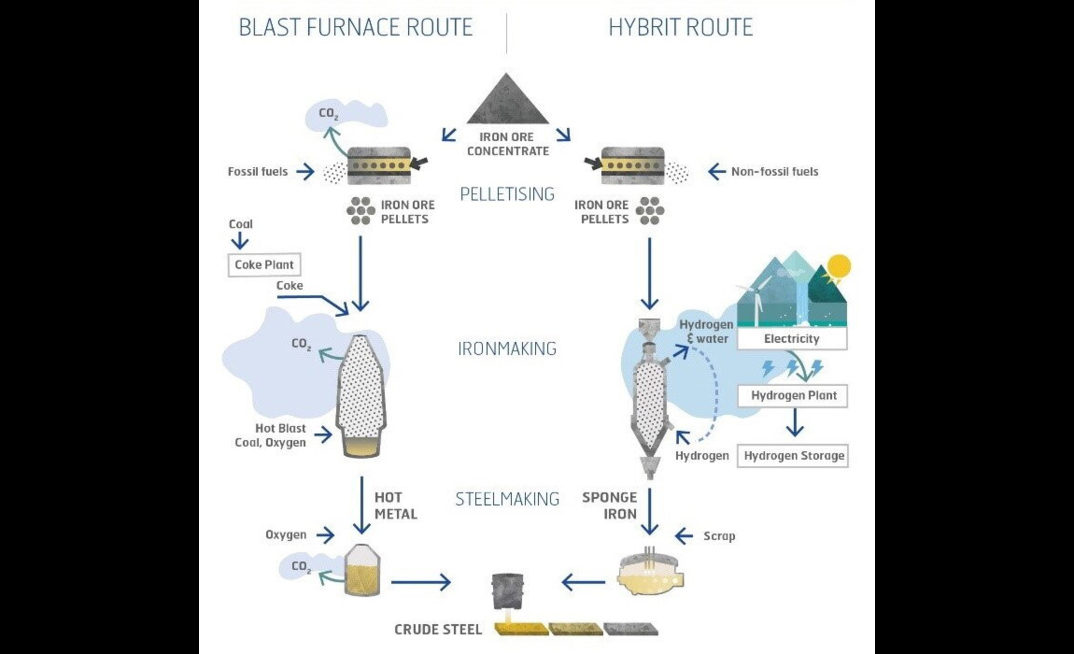

But how viable is this change to both a company's bottom line and the reduction of global greenhouse emissions? The current steel making process has remained largely unchanged for 150 years; iron ore is first smelted with carbon-rich coke in huge blast furnaces that emit carbon gases and churn out liquid metal. In theory, to replace the coking coal with hydrogen the reaction is similar, however, instead of producing carbon dioxide the only by-product is water vapor.

The technologies to make this iron reduction process a reality are not necessarily new, but such a change would need to be adopted at scale in order to deliver time and cost outcomes that encourage the change. Electrolysis is currently used to produce hydrogen in relatively low volumes and storage is also available, but again not at the scale required. However, if renewable electricity was used in the process of producing the hydrogen and the iron ore feed pellets, then a 98% reduction in CO2 emissions could be achieved when compared to the blast furnace-coke method. The economic viability of the hydrogen-based process is highly dependent on the availability of low-cost clean electricity or conversely, higher prices for carbon emissions across all nations.

Test plants have already been set up in Europe to trial this new process. One Swedish joint venture set up in 2016 between an iron ore mine, a steel manufacturer and a power utility company, with funding assistance provided by the Swedish Energy Agency, is trialling the concept of Hydrogen Breakthrough Ironmaking Technology (HYBRIT); their goal is to develop fossil free steel production.

The challenge to coal mining operations and associated industries is not necessarily that this new process is coming but rather that the same defensive arguments and platitudes that were used about renewable energy technology will be trotted out. Denial and delay will rob our industry and our society of a unique chance to develop and capture emerging opportunities.

Connect with Chris

https://www.linkedin.com/in/knowlescj/

Image

Homan, Q., (2019). Hydrogen as a Clean Alternative in the Iron and Steel Industry. Fuel Cell & Hydrogen Energy Association. http://www.fchea.org/in-transition/2019/11/25/hydrogen-in-the-iron-and-steel-industry

References

Lund University, (2018). Hydrogen Steelmaking for a low-carbon economy; a joint LU-SEI working paper for the HYBRIT project. https://www.sei.org/wp-content/uploads/2018/09/hydrogen-steelmaking-for-a-low-carbon-economy.pdf

Bloomberg News, (2019). How hydrogen could solve steel's climate test and hobble coal. https://about.bnef.com/blog/hydrogen-solve-steels-climate-test-hobble-coal/

ABOUT THIS COMPANY

McLanahan Corporation

Feeding, Crushing, Sampling, Dewatering and Scrubbing equipment.

HEAD OFFICE:

- 27 Kalinya Close, Cameron Park, NSW 2285, Australia

- Phone: +61 2 4924 8248

- Website: www.mclanahan.com.au

- Email: sales@mclanahan.com.au