Many of today's shearer automation methods position the floor drum in a way that mirrors the shape of the roof, at a predefined offset, away from the roof line. With this conventional practice, the shape of the roof is determined by the cut of the operator and every movement of the roof drum affects the position of the floor drum.

This method results in "roll oscillations" along the face. As the shearer hauls across the pans' bumps in the floor, it creates bumps in the roof due to system lag, which can result from things like sensor response and filtering or hydraulic response time. The bumps in the roof get reflected to the floor and the problem compounds itself with each pass. This has been a standard practice with operators proactively intervening, utilising the tools they have to stay in the seam.

The resulting challenges from roll oscillations include armoured face conveyor articulation creating stress and wear while increasing power demand, and positive pitch changes causing shearer drums to potentially collide with canopies.

With advancements in shearer automation, there are ways to stay in the seam with less operator intervention and better strata control, through maintaining a smooth floor. A smooth floor results in the most consistent and efficient cycle times, while minimising the need for human intervention.

An alternative to today's challenges

Pitch Steering is a new automated cutting method that applies to the floor drum, designed to position the drum at a height that maintains a preconfigured pitch angle of the pans. It accurately plans the cut based on gate road surveys and geological information. The target angle is intended to reflect the actual angle of the seam being mined.

This patent-pending system will position the floor drum to maintain this pitch angle unless an elevation change is required. To create an elevation change, a pitch correction is created by adding a positive or negative pitch offset to the target angle for that section of the face. The magnitude of the offsets is defined by the user during the commissioning phase, and results in a very predictable and controlled elevation change.

With the Pitch Steering system, the operator can instruct the shearer to execute controlled incremental elevation changes by entering corrections into the roof support mimics. The target angle can be updated offline and then uploaded to the shearer by the user as needed if conditions change.

With Pitch Steering, the operator can instruct the system to make an elevation change by entering a positive or negative correction across the desired range of supports and number of passes.

Pitch Steering is the latest enhancement to Joy's Advanced Shearer Automation (ASA) program and can be operated in an adaptive mode in seams where the advance angle changes drastically, with the system learning the changing seam angle and adjusting its set points accordingly.

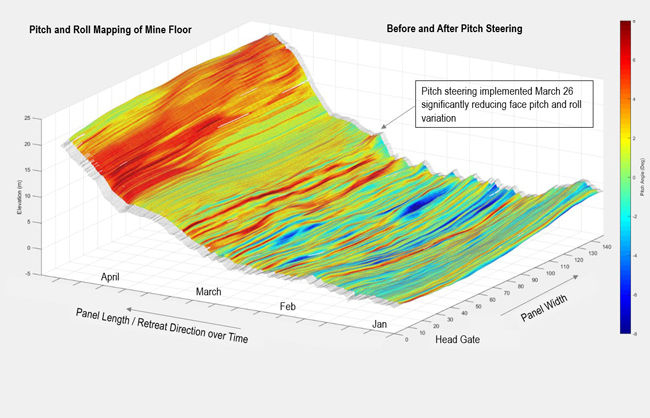

A floor elevation profile heat map depicting the face pitch and roll variation. When Pitch Steering was implemented at the end of March, there was a 40% reduction in pitch angle variation and a 29% reduction in roll angle variation.

Accuracy to drive results

Pitch Steering manages the floor as a controlled surface by limiting the amount of change in the floor per pass. The system scans the face and applies algorithms to maintain a smooth floor cut, providing benefits across the operation.

A smooth floor, with no drastic changes, allows the system to measure the surface accurately, producing a stable system, meaning less operator intervention is required.

The improved alignment of roof supports means better strata control and the reduced conveyor articulation saves time and money by reducing wear and tear. Pitch steering is also intended to prevent collisions between shearer drums and canopies by managing the maximum pitch change per pass.

The pitch steering process creates a more stable system so less operator intervention is required while maintaining better strata control.

The additional level of automation positions the operator farther away from the shearer and roof supports, driving high-production longwall mining while lessening the dust and noise to which the operator is exposed.

Pitch Steering system meets the challenge

The development of a 3D cutting simulation tool has allowed for enhanced testing of the feature by simulating the armored face conveyor pans being pushed onto the floor that the Pitch Steering system has created. This dynamic testing environment has allowed Komatsu Mining engineers to ensure the feature is designed appropriately to handle the challenging environment in which longwall shearers must operate.

Komatsu is also in the process of developing a new remote called a "Surveyor", where pitch steering correction can be entered remotely as an alternative to entering corrections into the PRS mimic.

Contact your local Komatsu representative to see how pitch steering can significantly reduce your total cost of ownership.

"To learn more about Pitch Steer automation visit-

ABOUT THIS COMPANY

Komatsu

OFFICE:

- 535 Progress Road, Wacol, QLD 4076

- Web: komatsu.com.au

- Email: info@komatsu.com.au

- Phone: 1300 566 287