Loadscan, leaders in load volume scanning for the past 20 years have found that most mines are regularly underloading their trucks. Underloading requires additional truck movements to shift the same amount of material, which can substantially reduce profitability and return on capital employed. Not to mention, the additional mileage prematurely wears out truck components and adds to fuel and running costs.

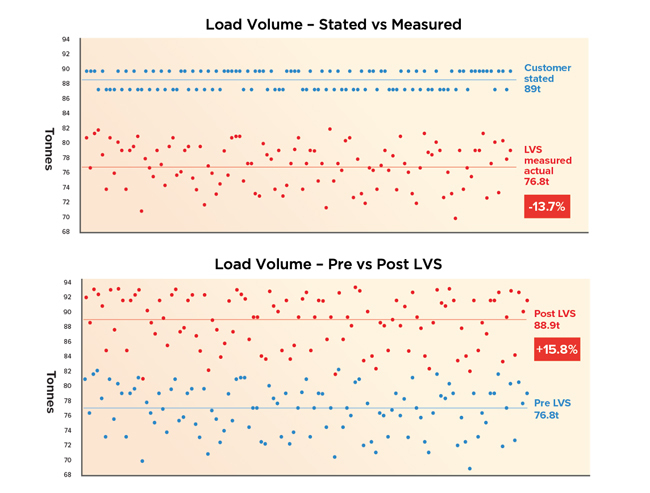

In one Loadscan customer example of a mine running a fleet of CAT777 trucks, they saw that stated load volumes were being over-reported by 13.7%. This discrepancy was only uncovered during a load audit study when a representative sample of loads were measured against actual load volumes scanned onsite with the Loadscan Load Volume Scanning (LVS) system.

The only volumetric scanning manufacturer with internationally recognised Weights And Measurement Certifications (Trade Approval Certificate 1556 (MAPPS NZ) and Pattern Approval Certificate 13/1/15 (NMI AUS), Loadscan LVS measurements are accurate to +/-1%. This high level of accuracy provides confidence for users in their measurement data, allowing for better-informed business decisions.

As a result of the load audit study insights, the customer purchased a Loadscan LVS. After implementing the LVS system they were able to increase actual loaded volumes by 15.8%. The Loadscan LVS accurately measures all loads and automatically generates 3D scan images that clearly indicate underloading, enabling corrective action (including operator training and coaching) to be taken.

In addition, the scans indicate if there is carryback in the bins, enabling it to be accounted for and deducted from shift tallies. This improves the accuracy of actual loads shifted. Plus, being aware of carryback enables the bin to be scraped out, further improving trucking factors and asset optimisation.

In the above customer example, underloading required 1,772 additional truck loads to shift 1,000,000 tonne material (based on a density factor of 1.8). By saving that many truck loads as a result of optimised loading they were able to substantially increase production and profitability, as well as improve return on their capital assets.

Scatterplots illustrate the level of underloading and the subsequent improvement post-LVS installation

Loadscan's business focus is on helping mines and civil operators optimise loading (and assets) by maximising every truck load, thereby increasing trucking factors, increasing production and improving business profits.

How confident are you that your trucks are being fully loaded? Click on the link to calculate how much value your operation could be losing due to underloading.

ABOUT THIS COMPANY

Loadscan

A successful family business that has grown from one man’s mission to accurately measure truckloads of material using volume laser scanning technology.

HEAD OFFICE:

- 27 Earthmover Crescent Burbush, Hamilton 3200 New Zealand

- Telephone: +64 7 847 5777

- Web: www.loadscan.com/

- Email: sales@loadscan.com