As the Future in Mining conference in Perth draws near, many in the industry are eager to hear Ian Jones' upcoming presentation. His talk is slated to offer valuable perspectives on how mid-tier mining companies can improve productivity and efficiency, even with leaner budgets. Surprisingly, 80% of mining companies remain unable to tap into the potential of systems employed by top-tier miners. By harnessing real-time fleet data within a mine's existing resources, iVolve collaborates with operations to maximise value for mid-tier miners.

iVolve's Iterative Change Model

A central point of discussion is expected to be iVolve's Iterative Change Model—Value, Focus, and Resource—to empower mid-tier miners to make the most of the resourcing and equipment they already have. Applying this approach has led to significant productivity gains for iVolve's customers which enables an ROI in less than one year.

VALUE: Ensuring customer benefits

When adopting new technology, pinpointing the precise areas where value will be generated is crucial for operational success. Collaborating intimately with the customer to identify and articulate key value drivers enables a rapid realisation of Return on Investment (ROI). By focusing on both the customer's strategic objectives and existing operational challenges, the deployment transcends mere technology implementation to offer substantial, impactful value creation for an operation.

FOCUS: Zeroing in on results

Attempting to address all pain points immediately during a technology rollout can undermine its effectiveness. A more focused approach is advisable, zeroing in on just one or two strategic operational areas to fully comprehend their nuances and the applicable technology. Collaborating with the customer ensures that stakeholders direct their attention and resources toward these critical value areas, facilitating real, incremental value creation.

RESOURCE: Smart solutions for budget-conscious miners

Acknowledging the resource limitations often faced by mid-tier mining operations, the focus is on leveraging existing assets to their fullest potential. A comprehensive evaluation of a mine's current resources—be it fleet, infrastructure, or personnel—lays the groundwork for customising the technology deployment. This strategy allows for significant gains in productivity and efficiency without the need for significant capital investment.

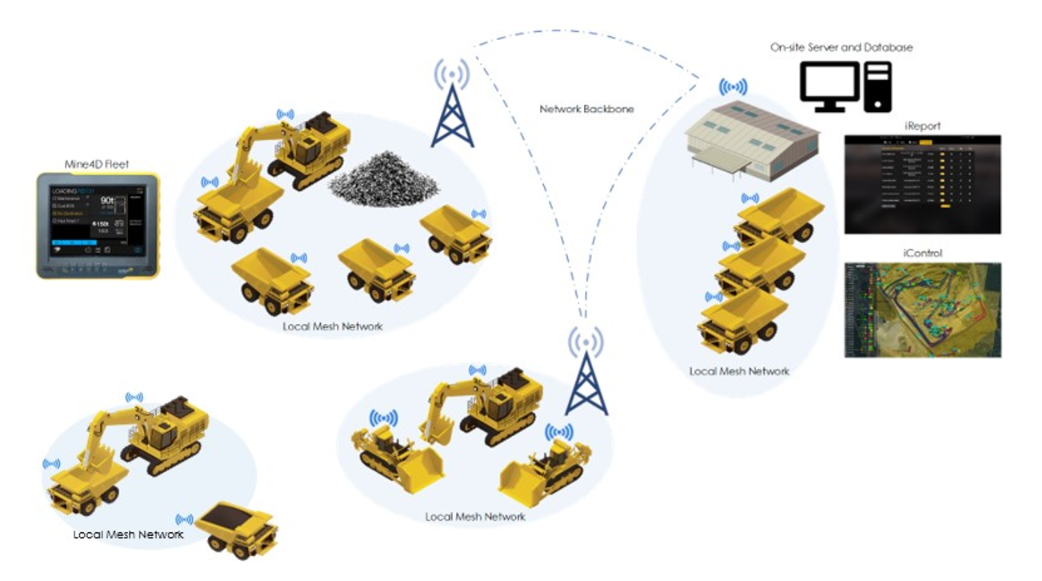

Mid-tier mining operations require a network architecture that can adapt to evolving site topography and expanding work zones. Designed with this specific need in mind, the Nexis platform eliminates the need for a dedicated mesh controller. This allows vehicles to stay connected to each other even when they are operating away from the network, reducing infrastructure costs and providing the flexibility to scale alongside the operation.

: iVolve's Mesh Network Overview

ITERATIVE CHANGE: What's the next focus?

Achieving the initial ROI is undoubtedly a significant milestone for any mining operation. After realising these initial gains, the operation can harness its rich, real-time data to turn its attention to the next key value point for enhancing operational efficiency, guided by the principles of the Iterative Change Model. The aim is to capitalise on the momentum achieved initially, fostering a culture of continuous improvement.

The availability of real-time fleet data opens a wide spectrum of possibilities for fine-tuning operations. This spans from optimising truck cycles and fuel efficiency to proactive vehicle health management and enhancing operator safety and efficiency. Moreover, capabilities like ore grade management, automated vehicle pre-starts, defect management, and even ESG reporting are now within reach. In essence, the scope for improvements is restricted only by the boundaries of one's imagination.

CASE STUDY 1

An application of the iVolve Iterative Change Model is well illustrated with an iVolve customer in the USA. The core concern identified was the delay and inaccuracies involved in the existing paper-based data collection and analysis process, which would take upwards of 24 hours. iVolve worked with the customer to focus on this critical bottleneck, streamlining automated data collection and analysis through its Fleet Management System (FMS). Addressing this single vital area enabled the operation to make significant improvements in productivity and operational efficiency.

Functional Improvements within 1 year of installation

Initial performance benchmarks were established prior to the technology deployment to allow ROI calculations. In addition to real-time and accurate data reporting, further benefits were realised in the subsequent deployment iteration which focused on payload improvement. Automated data also allowed accurate measures in other areas including cycle times and haulage costs.

The iVolve FMS was deployed on a CAT 992 wheel loader, two CAT 990 wheel loaders, and four CAT 777 trucks. The result of the payload focus iteration was a shift from an average tonnage of 95 tons to 99 tons, marking a 5% increase. Moreover, the potential productivity gain of 12% underlines further improvements that are possible as the system becomes entrenched in the site's operations.

CASE STUDY 2

Another illustration of this iterative approach can be seen at an Australian site. This particular site had issues with consistent truck underloading. iVolve worked with the customer to focus on this critical bottleneck through training, automated data capture and truck operator displays and the production dashboard.

Operators were shown how the iVolve system gave them instant feedback in-cab so they knew they were getting maximum tonnage on each load. Dispatch and management were shown how to use the iVolve system dashboards and reporting functionality to plan, oversee, and report on each shift to maximise efficiency.

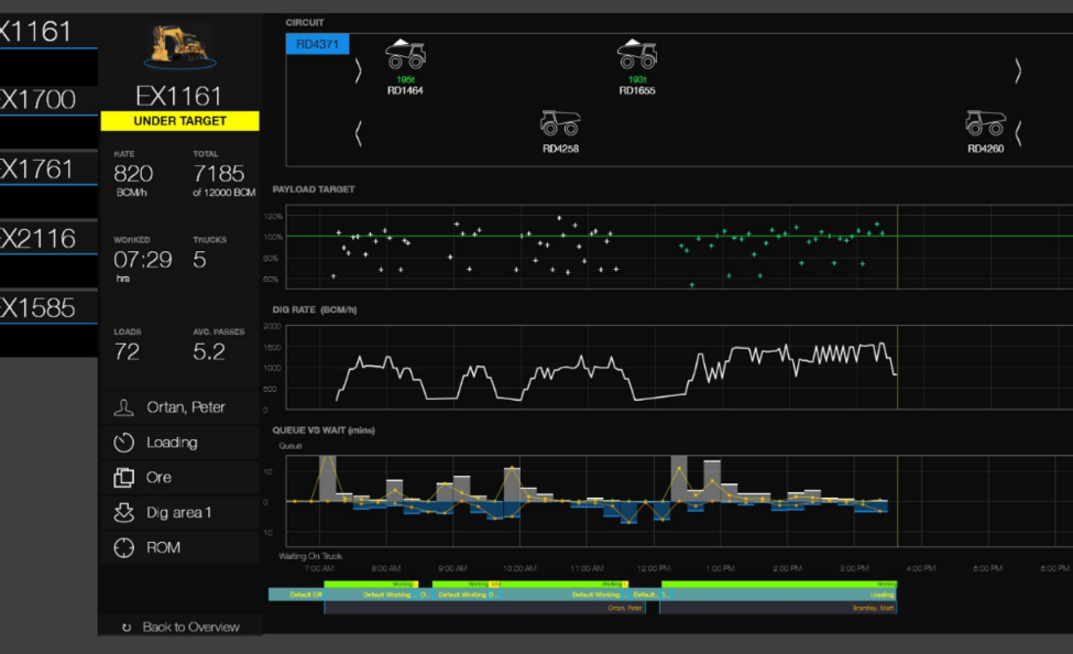

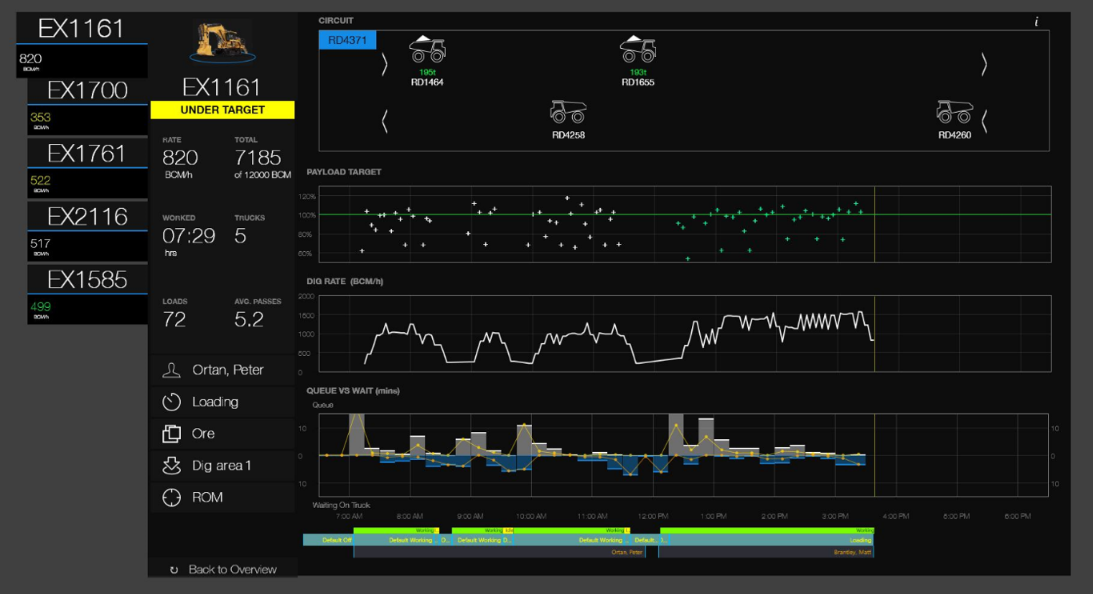

Production Dashboard

Providing a real-time snapshot across the entire site production fleet, the Production Dashboard utilises user-friendly graphic visualisation tools, aiding dispatch personnel and shift managers in timely decision making.

Addressing Underloading at Site

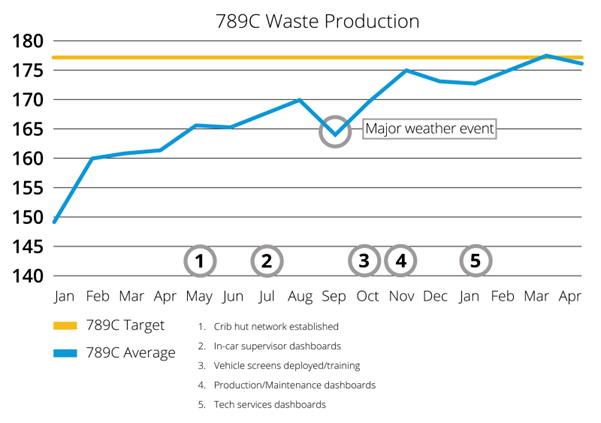

Utilising the iVolve Iterative Change Model, the deployment spanned a 12-month period with staged introduction of capability. This enabled site operations to focus on each new improvement, engaging relevant personnel at each stage, which in turn encouraged by-in and uptake of users at all levels.

Through these efforts, average tonnage surged from 150-160T to 175-177T post iVolve implementation, indicating a 9.1% increase in overall production.

A Model for Future Mining Operations

As Ian Jones will illuminate in his upcoming presentation at the Future of Mining Perth conference, mid-tier miners are now, more than ever, in a prime position to leverage the power of data to unlock fleet value. iVolve's success story with this US and Australian site, stands as a poignant example of how a thoughtful, three-pronged approach of Value, Focus, and Resourcing can lead to significant productivity gains and a rapid ROI—even for operations with constrained budgets.

To learn more about iVolve solutions, visit the Future of Mining Perth conference and listen to Ian Jones' presentation titled ‘Mid-tier miners - unleashing the power of data to unlock fleet value' at 11:40 am on Monday, the 18th of September.

ABOUT THIS COMPANY

iVolve

iVolve® is an Australian-based company offering technology and tools to mine owner-operators and contractors, helping them enhance efficiency in an increasingly competitive market. By providing real-time data access from mobile assets, iVolve enables customers to make informed decisions for day-to-day operations and strategic planning.

HEAD OFFICE:

- Level 6, 52 Merivale Street, South Brisbane QLD 4101, Australia

- Telephone: (07) 3253 6700

- Web: www.ivolve.com

- Email: info@ivolve.com