SIMEC Mining Inner Harbour in Whyalla, South Australia

SIMEC Mining's Inner Harbour operation is located at Whyalla Port, on the western shores of the upper Spencer Gulf in South Australia. Whyalla has a rich history in steel with the first discovery of Iron Ore occurring in the region in the mid-1800s. By the end of 1901, Whyalla (then known as Hummock Hill) was born, as the construction of a jetty to load the ore onto barges started, and the population of the town began to grow. Today, Whyalla Port deals with much higher tonnages, exporting iron ore to customers around the world.

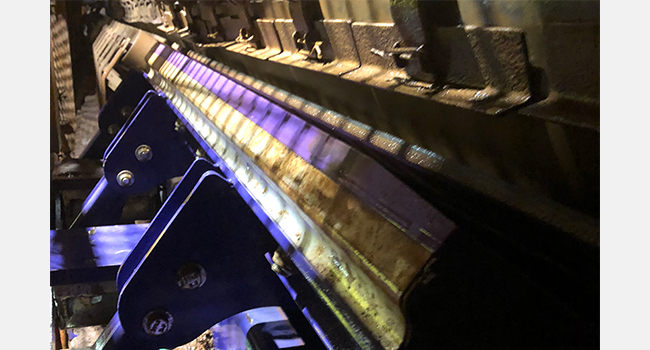

At SIMEC Mining's Inner Harbour operation at Whyalla port, product spillage generally occurs due to inadequate material containment, coupled with high tonnages. Conveyor 10-CC-001 handles severe loads which were causing major issues for the iron ore site. Most notably, the site was regularly dealing with broken idler frames, extensive product spillage, and considerable belt damage. As a result, SIMEC Mining and BIS Industries, their contractor on site, identified this system as an opportunity to implement serious enhancements. Their goal was to minimise spillage and product wastage, stop damage to the structure, idlers, and belt, reduce the time spent cleaning up, make maintenance on the system safer and easier, and increase overall productivity on site.

Paul Whitehouse, SIMEC Mining Rail and Ore Facilities Manager, and Mark Richards, BIS Industries Maintenance Supervisor, were the personnel in charge of the planning and execution of the upgrade on conveyor 10-CC-001.

Conveyor 10-CC-001 handles severe loads of 2,800 tonnes per hour of iron ore fines dropping from a height of seven metres on to the receiving belt, which moves at 3.6mps. The belt takes Iron Ore fines from the train's tip pocket to the shuttle conveyor and delivers into sheds filled with overburden. It is the only belt on a single line system, so the mine depends on its efficiency.

Richards said that the central issue with the current impact frames and idlers was the severe product spillage.

"We were seeing large amounts of spillage from the conveyor chute, impacting floor cleanliness and obstructing access to the tail section of the conveyor. Spillage was also impacting operations due to a large amount of build-up of product causing carryback and tracking issues. Due to the falling height of the product, we were finding premature wear and damage to the impact idlers and frames," Richards explained.

The spillage amount was so great that the tip pocket required a 12-hour shut down, once a week for the sole purpose of clean up.

"We would have to shut down the in-loading circuit for 12 hours and carry out cleaning tasks to allow us to inspect and maintain the plant safely. This was impacting train operations and shed in-loading operations," said Richards.

In order to safely undergo the clean-up, a vacuum truck would have to be hired from a contractor to assist with the spillage clean up. It only took the load of two trains for this high build of spillage to occur. The system was supposed to service 17-18 trains per week.

On top of the regular cleaning, side skirts would also need to be replaced on a weekly basis, along with the inspection and replacement of idler frames. The previous impact frames and idlers were not only limiting efficiency, but also costing the mine a huge amount of money in extra labour hours and replacement parts.

Custom Flexco DRX4500

Heavier Duty Structure

After discussions with both SIMEC Mining and their service contractor, Fenner Dunlop, Flexco engineers custom-designed a new impact bed, the DRX4500, to cope with the high drop height and severe tonnages. The impact bed was specifically designed to minimise spillage and also to protect the skirting of the conveyor system as it features two levels of impact-absorbing force reduction.

The DRX impact bed was able to effectively replace the previous set up, which featured frames placed in close proximity with impact idlers installed. This set up was ineffective as well as costly. The idlers were shattered by the impact energy of the drop, and the cost and regularity of replacement meant wasted time and money spent on maintenance.

The DRX impact bed also enabled SIMEC and Fenner Dunlop to service the impact bed more easily than the previous structure. The bed separates in the middle, allowing the two sides to slide apart for easy, and more importantly, safer maintenance.

Results in just three days

The outstanding results began to show just three days after the installation of the DRX4500. When beginning the project, SIMEC had a goal in mind - to tip 17-18 trains per week. Just three days after this installation, Whyalla Port tipped 17 trains in only three days with minimal build-up of product on the ground.

Richards explains how enormous amounts of time and money was saved in clean up and maintenance.

"Previously we were using a vac truck weekly, but that has now been pushed out to once every six weeks. Due to the positive sealing effect of the impact beds, we are finding there is minimal airborne dust and spillage and no need to replace idlers and frames in this area since the impact bed installation [nine months ago]. Apart from regular inspections and side skirt adjustments, the area is virtually maintenance free," says Richards.

The maintenance task is now down to one member, who goes down to the tip pocket to hose once a week to clear away the residual carryback and a small amount of dust which has settled on the floor. Apart from the success of limiting maintenance needs, there have also been definite improvements in belt tracking at the tail drum area.

When asked about how happy SIMEC was with how Flexco and distributor, Fenner Dunlop handled the situation, Richards said he was extremely happy that "an engineering solution was put forward, plan put into place, and installation carried out by Fenner Dunlop on time and on budget. The project was completed with minimal downtime and inconvenience to the client and operations. All involved in the task worked in a safe and responsible manner and were diligent in their duties."

Richards concludes, "the most important outcome was to provide a safe working environment for all persons in that area. If that could be achieved by minimising spillage from that chute, then we could reduce vacuum truck cleaning, minimise labour for maintenance, and increase housekeeping efforts. The impact beds had been implemented because we had seen them utilised in other areas of the plant and had observed the difference they make."

The team at SIMEC Mining and BIS Industries are looking to the future. Not only do they have another proven solution to help tackle maintenance problems down the track, but they also have a trusted team of experts they can call on who can look at the conveyor system holistically and offer custom solutions to tricky issues.

To find out more about how Flexco impact beds can help your site minimise maintenance needs, contact technicalsupport@flexco.com.

ABOUT THIS COMPANY

Flexco

Flexco is focused on becoming your number one resource for products and services that maximise your belt conveyor uptime, productivity and safety. With over 110 years of experience in solving belt issues around the world, we are committed to keeping both your belts and business moving.

HEAD OFFICE:

- Flexco (Aust.) Pty. Ltd, 10 Solent Circuit, Norwest NSW, Australia, 2153

- Phone: 88182000

- Website: flexco.com.au/

- Email: salesau@flexco.com