FLSmidth has been proactive in this approach, forming a tailings-focused subdivision within its company seven years ago, director of tailings solution Kenneth Rahal said.

"So many of our customers are just looking at all the different options" when it comes to tailings technology, he said. "They want to better understand the costs associated with different technologies - whether it be just normal thickening or paste thickening or filtered tailings - as well as the different technologies that would go into the flow sheets."

As a result, rather than just receiving general presentations from OEMs (Original Equipment Manufacturers) about potential technologies, "some customers are now looking at pilot-scale technologies" to explore the scalability of these new technologies, Rahal said. "They want to collect more data to become familiar with these alternative tailings solutions.

Optimising flow sheets

One technology that FLSmidth has been working on is an improved overview system for mining operations.

"There's been a push within our digital group to improve both the Advance Process Control [APC] systems as well as the sensor technology," Rahal said.

The APC system stabilises key processes in the mining flow sheet and manages and corrects unforeseen process disruptions. This technology also works to minimise wear of equipment, extending its life, while reducing the overall operational and maintenance costs.

The system will also optimise mill load targets, meaning that it will automatically adjust the mill load according to both the weight target set by customers and the process conditions.

FLSmidth has employed model predictive control and fuzzy logic rules to maximise the efficiency of this new process tool. The model predictive control undertakes calculations to optimise performance and how different machine parts interact with each other. The APC system works with targets as set by the customer, and ensures that the process is adjusted to meet these specified targets.

The system also employs artificial intelligence (Symbolic and Non-symbolic) in its optimisation strategy for processes.

The various ‘symbolic technologies', as termed by the company, are used for high-level problems that are readable by humans. These include fuzzy logic, which delivers rules-based, intelligent fuzzy control. The ‘non-symbolic technologies' include providing raw data to the machine and allowing it to recognise patterns. These include machine learning and deep learning.

The APC system also incorporates a soft sensor known as the Kalman filter to generate readings in situations where signals cannot be interpreted or are unavailable.

With these benefits, no challenge is too difficult for the APC system to manage - whether it be a mining company implementing extensive upgrades to their plant or testing new strategies for process control.

Comminution upgrades

FLSmidth has also been hard at work stepping up its offerings for the all-important comminution cycle.

Sensor technologies have been critical in improving efficiency and reducing waste, Rahal said.

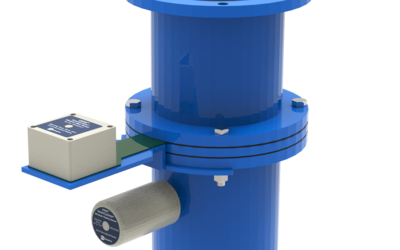

"Our digitalisation efforts are looking all the way up into the combination circuit, where we've developed our LoadIQ® sensor technology," he said.

The LoadIQ® sensor technology aims to enable miners to increase mill throughput without investing in costly upgrades for the grinding mill. The technology developed by FLSmidth will allow operators to determine how full the mill is at any moment, as well as where charges are located in the grinding mill. The LoadIQ® software can also determine where the cascading material is most impacting the liner, to better protect the liner from excessive wear and tear and extend its life.

FLSmidth's LoadIQ® is a smart load optimization tool for SAG and AG mills

The software also decreases the amount of time required to process changes in ores and liners, and to determine optimal load targets. LoadIQ® will enable miners to calculate these targets efficiently, and has the option of being set to manual for operators to control it directly. Otherwise, LoadIQ® also offers the option to feed these factors into any system via Open Platform Communications to enable real-time optimisation.

By using AI-based software, FLSmidth is able to efficiently calculate optimal loads, work with installed expert systems, and ensure that point changes set by these expert systems - the DCS/PLC response - is never interfered with.

SmartCyclone™ technology

Focusing on improving the flowsheet from start to finish will ultimately improve the end product and tailings production, Rahal said.

This goal is further advanced by the development of FLSmidth's SmartCyclone™ technology, he added. This technology not only improves mineral recovery rates - an important outcome for all mining companies - but also increases overall production capacity and improves wear part monitoring.

The technology reduces - and at times, eliminates altogether - coarse particle bypass to the cyclone overflow, by lowering the number of variations in flotation particle size distribution. This will lead to fewer fines in the overall tailings process. Reducing standard deviation for particle size variation is critical to the overall improvement of the mineral recovery systems.

FLSmidth's SmartCyclone™ monitors wear and roping to optimize performance

SmartCyclone™ also expands production capacity by monitoring the roping process, Rahal said. Often in processing, cyclones can become overloaded and experience roping, which ultimately leads to a greater number of coarser solids winding up in the overflow. By reducing the amount of roping, the SmartCyclone™ stabilises the entire secondary grinding circuit, FLSmidth said. The SmartCyclone™ technology reduces over-grinding in the mill and means there are fewer fine tailings that are generated, Rahal said.

The SmartCyclone™ package comes in two forms: ‘Basic', which includes roping and wear sensors along with associated alarms, and ‘Expert'. The Expert package includes the roping and wear technologies, along with condition-monitoring based operation, sump-level control and pump optimisation. It also includes cyclone overflow particle size estimation, cyclone inlet pressure optimisation, cyclone overflow optimisation, cyclone inlet density/solids optimisation, circuit production maximisation, and cyclone balancing based on wear and operating time.

ABOUT THIS COMPANY

FLSmidth

FLS is a leading, full flowsheet minerals processing supplier to the global mining industry. We deliver proven technologies and services across the lifecycle of operations, and have set targets of providing solutions for zero-emissions mining by 2030 with our MissionZero programme.

HEAD OFFICE:

- FLSmidth A/S Vigerslev Allé 77 2500 Valby, Copenhagen

- Tel: 4536181000

- Website: www.flsmidth.com

- Email: info@flsmidth.com